- Joined

- Jan 7, 2003

Your hands must be feeling better? Braiding that wire musta sucked.

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

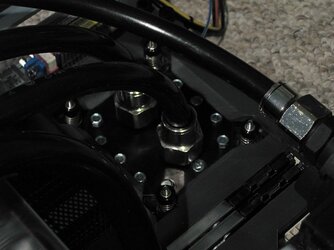

Captain Slug said:No, I'm using a PVC 1/4" NPT Female Tee with two swivel fittings and the drain valve. The swivels will allow me to orient the drain valve in whatever direction I want so that I can keep the filling cup upright while bleeding, then tip it out to empty it after closing off the valve.

Mcmaster has 8 or 9 pages of "instant-tube fittings". The Nickel-plated brass ones I'm using are on page 171. If you need any other kind of fitting search for "pipe fittings" then select your preferred material.greyharte said:okies ... let me re-phrase then ... where are you getting reliable leak-proof swivel fittings and it also makes me thing some quick-connects would be cool too ... that way one could hard mount a fill port and disconnect when one needs to drain ... got me thinking, since im getting ready to redo my loop soon ... any source info and pricing would be greatly appreciated

It's a completely separate project that I've been tinkering with for a year now. However, when completed it also will be stylistically very similar to the gatling guns seen in Metal Slug.Angel-of-Sorrow said:I can't wait to see that gun made.

Where do you plan on mounting it, Slug?

Actually has nothing to do with the watercooling. The cover simply helps me hide all of the wires running from the bottom area of the motherboard up to the power supply.sephiroth_749 said:i hate to be a noob of water cooling but why is the mobo covered?

1. Correct. They would very differently from other fittings.RonaldoR9 said:1. So these "instant tube fittings " you don't need clamps or anything to secure them do they work like compression fittings or what?

2. You are using 1/2 inch tubing?

3. Im asking beacuse i always wanted to use compression fittings exept they dont make it for 1/2 inch tubing do u have a link to where you bought those.