- Joined

- Dec 7, 2003

VESA Wall Mount Project

*** This is the complete build log in real time as I built this project. If you wish to skip right to my "Completed this Project" thread, click -->here<-- ***

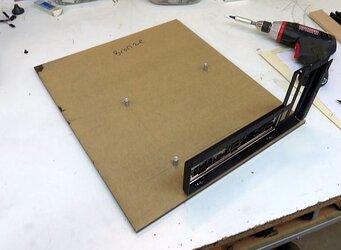

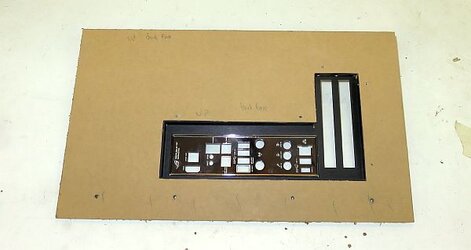

There are number of great Wall Mount PC mods out there. I guess I would define a Wall Mount mod as having the components all laid out flat on a flat surface, hung vertically, and on full display like a picture frame.

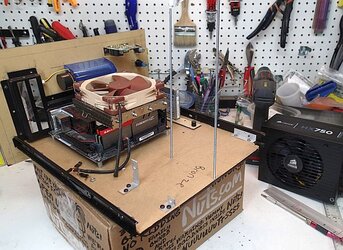

I did my own take on this type of mod in my project, the Vertical Benching Station. (I apologize, thanks to photobucket all my pics got screwed, so I am in the process of re-hosting all of them).

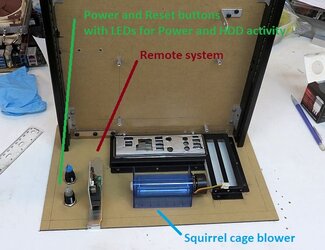

This is actually my current personal gaming system. I sort of blended my own style of benching station with a wall mount mod--although instead of a wall, I used pegboard.

While I was building this project, a poster suggested I do a wall mount project specifically to go with a large screen TV.

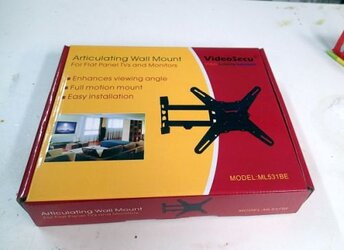

I thought about different ways to combine a PC system and a big screen TV--On the one hand you could have a wall mounted PC just sort of hanging out behind or near a big screen TV. The big screen TV would just be separately mounted on a VESA wall mount bracket (VESA is the standard to make sure all your mounting screw holes line up between the back of your TV and the bracket). Just pulling from the web, something like this.

On the other hand, you can also build a mini or micro-ITX system into a component sized case, and just add it to your stack of components. Plenty of off-the-shelf cases for this like this from Silverstone.

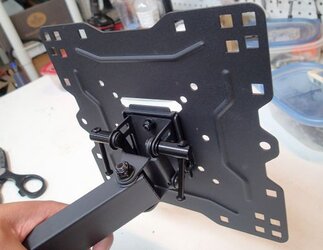

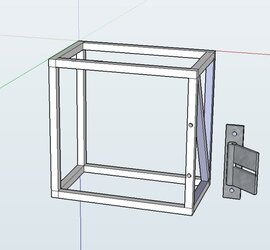

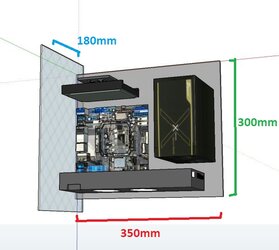

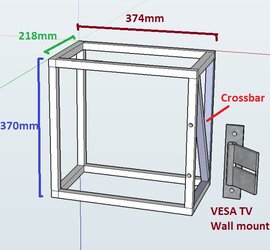

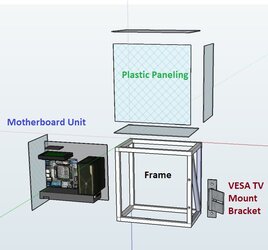

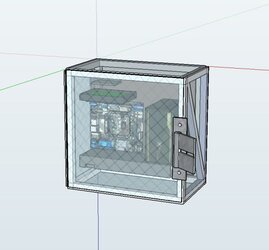

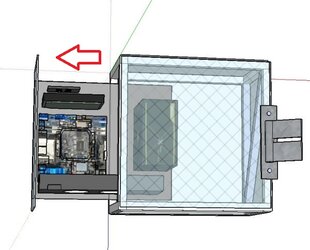

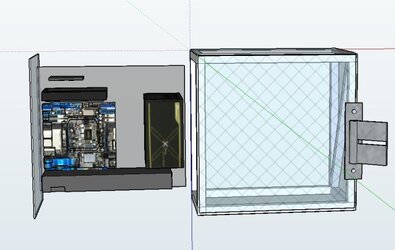

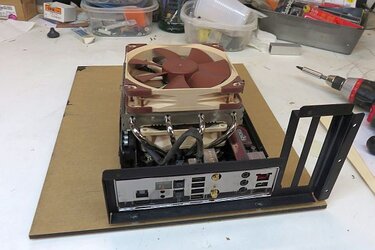

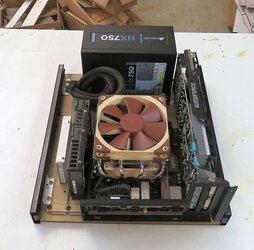

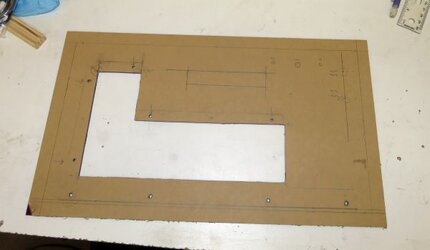

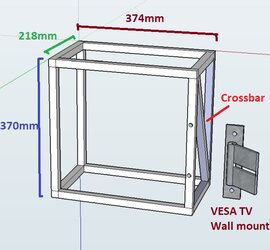

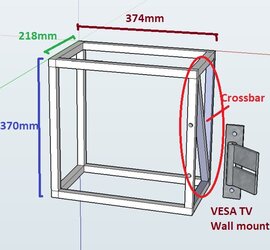

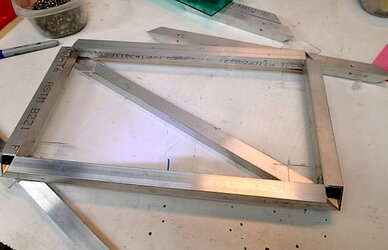

I decided to take it one step further and do something I’ve not seen before--why not build the big screen TV mount right into a computer case? Have the TV bracket integrated right into the case. That way you just mount the case to the wall. Then hang your TV from the case.

Wall Mount PC + VESA standard TV bracket = Navig’s Wall Mount VESA Project

*** This is the complete build log in real time as I built this project. If you wish to skip right to my "Completed this Project" thread, click -->here<-- ***

There are number of great Wall Mount PC mods out there. I guess I would define a Wall Mount mod as having the components all laid out flat on a flat surface, hung vertically, and on full display like a picture frame.

I did my own take on this type of mod in my project, the Vertical Benching Station. (I apologize, thanks to photobucket all my pics got screwed, so I am in the process of re-hosting all of them).

This is actually my current personal gaming system. I sort of blended my own style of benching station with a wall mount mod--although instead of a wall, I used pegboard.

While I was building this project, a poster suggested I do a wall mount project specifically to go with a large screen TV.

I thought about different ways to combine a PC system and a big screen TV--On the one hand you could have a wall mounted PC just sort of hanging out behind or near a big screen TV. The big screen TV would just be separately mounted on a VESA wall mount bracket (VESA is the standard to make sure all your mounting screw holes line up between the back of your TV and the bracket). Just pulling from the web, something like this.

On the other hand, you can also build a mini or micro-ITX system into a component sized case, and just add it to your stack of components. Plenty of off-the-shelf cases for this like this from Silverstone.

I decided to take it one step further and do something I’ve not seen before--why not build the big screen TV mount right into a computer case? Have the TV bracket integrated right into the case. That way you just mount the case to the wall. Then hang your TV from the case.

Wall Mount PC + VESA standard TV bracket = Navig’s Wall Mount VESA Project

Last edited: