- Joined

- Nov 21, 2018

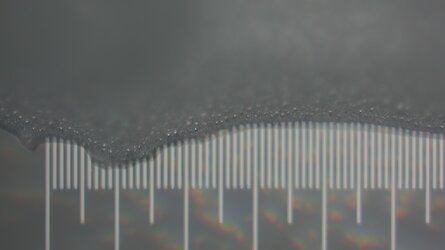

Bare with me I could not get to one of our good inspection scops so I'm using a beat up engineering scope. But I'll update the pics when they are finished inspecting wafers.

Start off these are both excellent paste and you can't go wrong with either one. So let's see what they look at under high magnafcation.

The average size for the NT-H1 was around .75um. why the Nano was around .58um. but the nano also has diamonds in it. They come in at around 5um in size.

From my testing I found the Nano to be around 2c better then the NT-H1. And it's clear why. The big gaps are filled by the 5um diamonds why the smaller gaps are filled with the .58um meterial. You can effectively fill larger gaps better and can fill smaller gaps the NT-H1 can not. I would have no problem running either one. They are consistent and high quality.

I'll update this with better pictures when I can. But here's a few I took on a scope we don't use for stuff this small. Typically we only lol at stuff around 200um because the resalution kinda sucks on it. But I'll take the pictures again on a scope we use for sub micron inspection.

NT-H1

[

- - - Auto-Merged Double Post - - -

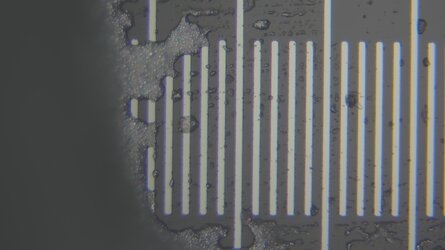

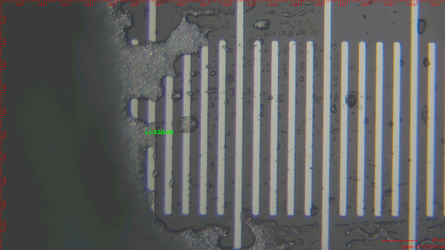

Coolermaster Mastergel Maker

Start off these are both excellent paste and you can't go wrong with either one. So let's see what they look at under high magnafcation.

The average size for the NT-H1 was around .75um. why the Nano was around .58um. but the nano also has diamonds in it. They come in at around 5um in size.

From my testing I found the Nano to be around 2c better then the NT-H1. And it's clear why. The big gaps are filled by the 5um diamonds why the smaller gaps are filled with the .58um meterial. You can effectively fill larger gaps better and can fill smaller gaps the NT-H1 can not. I would have no problem running either one. They are consistent and high quality.

I'll update this with better pictures when I can. But here's a few I took on a scope we don't use for stuff this small. Typically we only lol at stuff around 200um because the resalution kinda sucks on it. But I'll take the pictures again on a scope we use for sub micron inspection.

NT-H1

[

- - - Auto-Merged Double Post - - -

Coolermaster Mastergel Maker