- Joined

- Nov 26, 2004

- Location

- 1337 Leet Street , CO 1337

Got real bored today, Ive been waiting on my radiator i bought from someone on [H], bought it last wednesday, he said he shipped it yesterday, but it looks like he just printed the label..Anyways...

Decided to lap my CPU its a D0 i7-920.

I bought some super-cheap sandpaper from eBay

http://www.ebay.com/itm/181077403162?ssPageName=STRK:MEWNX:IT

http://www.ebay.com/itm/170986577257?ssPageName=STRK:MEWNX:IT

$15 shipped for a few sets of kits is pretty good IMO, they are pretty narrow, but work fine for me.

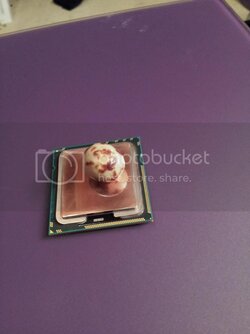

anyway heres the cpu stock:

\/\/\/\/\/\/\/\/

started by adding some electrical tape, covering all the circuits and so:

\/\/\/\/\/\/\/\/

(maybe you noticed, I'm trusting my trusty IceMat mousepad as my superflat glass surface haha)

1 sheet of 400 grit gone

\/\/\/\/\/\/\/\/

another sheet of 400

\/\/\/\/\/\/\/\/

I wish i had got some 250 grit, this thing was super warped, took 6 sheets of my 400 grit to get it smooth

\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/

finally smooth(er)\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/

after some 800 grit \/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/

now some 1500 grit \/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/

2000 grit(anyone try mountain dew throwback?)

\/\/\/\/\/\/\/\/

2500 grit

\/\/\/\/\/\/\/\/

(thats a shadow of my dresser in the back of the reflection)

polished and done.\/\/\/\/\/\/\/\/

hopefully I get my rad this weekend, so i can post up some pics of my setup

Decided to lap my CPU its a D0 i7-920.

I bought some super-cheap sandpaper from eBay

http://www.ebay.com/itm/181077403162?ssPageName=STRK:MEWNX:IT

http://www.ebay.com/itm/170986577257?ssPageName=STRK:MEWNX:IT

$15 shipped for a few sets of kits is pretty good IMO, they are pretty narrow, but work fine for me.

anyway heres the cpu stock:

\/\/\/\/\/\/\/\/

started by adding some electrical tape, covering all the circuits and so:

\/\/\/\/\/\/\/\/

(maybe you noticed, I'm trusting my trusty IceMat mousepad as my superflat glass surface haha)

1 sheet of 400 grit gone

\/\/\/\/\/\/\/\/

another sheet of 400

\/\/\/\/\/\/\/\/

I wish i had got some 250 grit, this thing was super warped, took 6 sheets of my 400 grit to get it smooth

\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/

finally smooth(er)\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/

after some 800 grit \/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/

now some 1500 grit \/\/\/\/\/\/\/\/\/\/\/\/\/\/\/\/

2000 grit(anyone try mountain dew throwback?)

\/\/\/\/\/\/\/\/

2500 grit

\/\/\/\/\/\/\/\/

(thats a shadow of my dresser in the back of the reflection)

polished and done.\/\/\/\/\/\/\/\/

hopefully I get my rad this weekend, so i can post up some pics of my setup