- Joined

- Dec 6, 2010

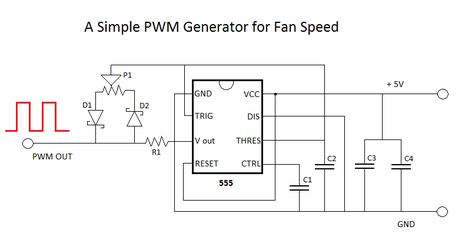

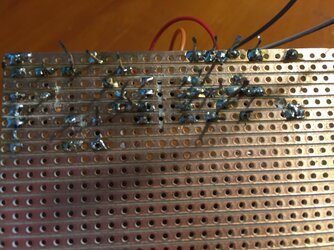

I've just recalled a regular diode like the ones we use here have limited frequency capability. PWM signal is supposed to be 25 kHz. Don't you guys think the two diodes in the project should be schottky diodes?

For the frequency used with PWM, silicon diodes are fine. I looked at that video and that guy is wrong on current flow in the diodes, it's from cathode to anode against the arrow , NOT anode to cathode with the arrow.

This got started way back in the 1800's when batteries were fist made, people thought that current went from + to -, when vacuum tubes came about, they found out that it went from - to +, but some people did not want to change their way of thinking, so we now have Conventional current flow (+ to -) and Real current flow (- to +).