WhichWayThat

New Member

- Joined

- Apr 1, 2018

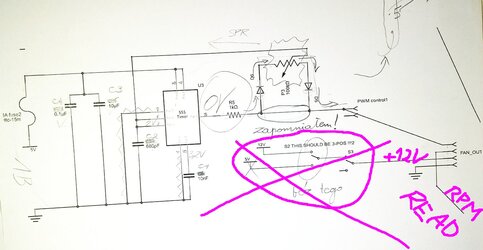

PWM Control Using Analog 0-5v input instead of potentiometer

I have a unique problem and have not been able to find a solution.

I am working on an older MSI 848P Neo2-V motherboard (MS-7108) which appears to be wired incorrectly.

The CPU Fan has a four pin fan header but the fan always runs at full speed.

The problem is the motherboard is wired direct from the output of the W83627THF chip with no additional circuitry.

It is wired to the correct pin on the Winbond chip, unfortunately this does not output PWM, but a 0 to 5 volt analog DC voltage signal.

This output on other MSI boards researched is manipulated by an OP-Amp setup and varies the fans DC input voltage using a three pin header fan setup.

On this board the output is being sent directly to the fourth header pin, which is not a PWM signal but the analog DC voltage.

Using Speedfan, I am able to change the output voltage at this pin from 0 to 5 volts in .33 volt increments (15 steps).

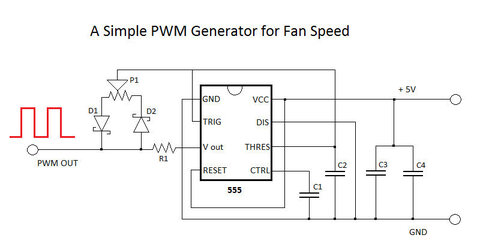

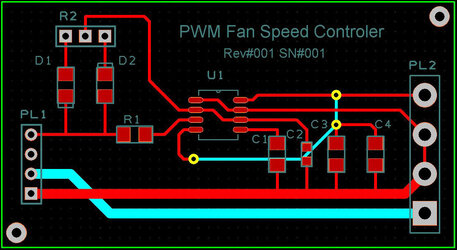

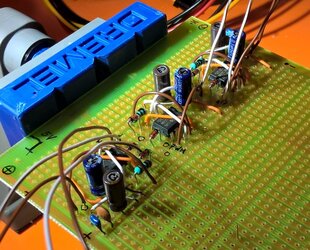

Is there a way to build this simple PWM Fan Controller using this analog voltage output in place of the potentiometer to vary the PWM output?

Any help appreciated - Thanks in advance - Rich

I have a unique problem and have not been able to find a solution.

I am working on an older MSI 848P Neo2-V motherboard (MS-7108) which appears to be wired incorrectly.

The CPU Fan has a four pin fan header but the fan always runs at full speed.

The problem is the motherboard is wired direct from the output of the W83627THF chip with no additional circuitry.

It is wired to the correct pin on the Winbond chip, unfortunately this does not output PWM, but a 0 to 5 volt analog DC voltage signal.

This output on other MSI boards researched is manipulated by an OP-Amp setup and varies the fans DC input voltage using a three pin header fan setup.

On this board the output is being sent directly to the fourth header pin, which is not a PWM signal but the analog DC voltage.

Using Speedfan, I am able to change the output voltage at this pin from 0 to 5 volts in .33 volt increments (15 steps).

Is there a way to build this simple PWM Fan Controller using this analog voltage output in place of the potentiometer to vary the PWM output?

Any help appreciated - Thanks in advance - Rich