In my next design I plan on having a single, central, top feed with the same four outlets. This will carry the heat AWAY from the core.

The new design is also a larger copper block.

I am currently undecided on how to implement a central spring system to guarantee even pressure. This is a problem many designs have.

Those water lines are "flex" lines typically found under your sinks. I use them frequently and they NEVER leak. There is a rubber tube inside the braided casing.

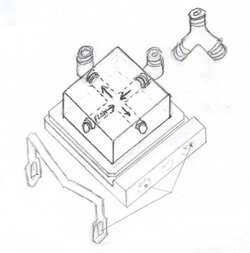

As you can see from my first hand drawn draft that my design changed a little during fabrication.

Note that my design is all copper .... I originally intended to use an old refigerator but having built another fidge rig I know all to well the toils of condensation. If I do go fridge again I will have to put my rig INSIDE another fridge to reduce ambient temps so I can apply even more cooling via phase change :> ...

I've got my recipricating saw ready to rip that old fridge apart! Stay tuned ...