- Joined

- Aug 20, 2023

- Thread Starter

- #21

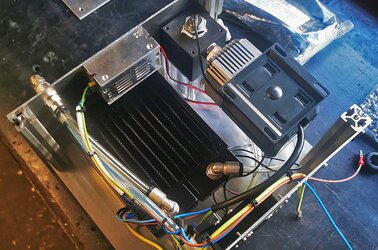

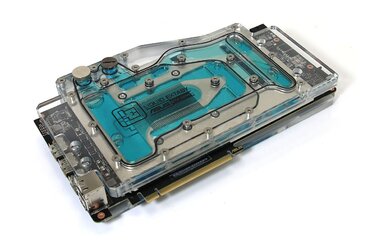

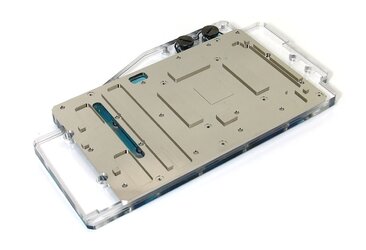

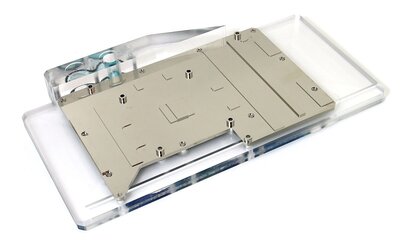

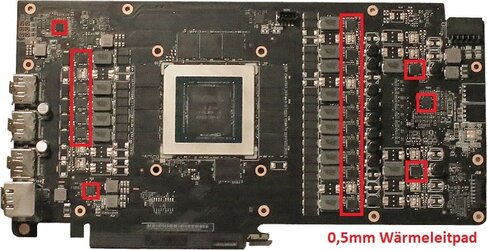

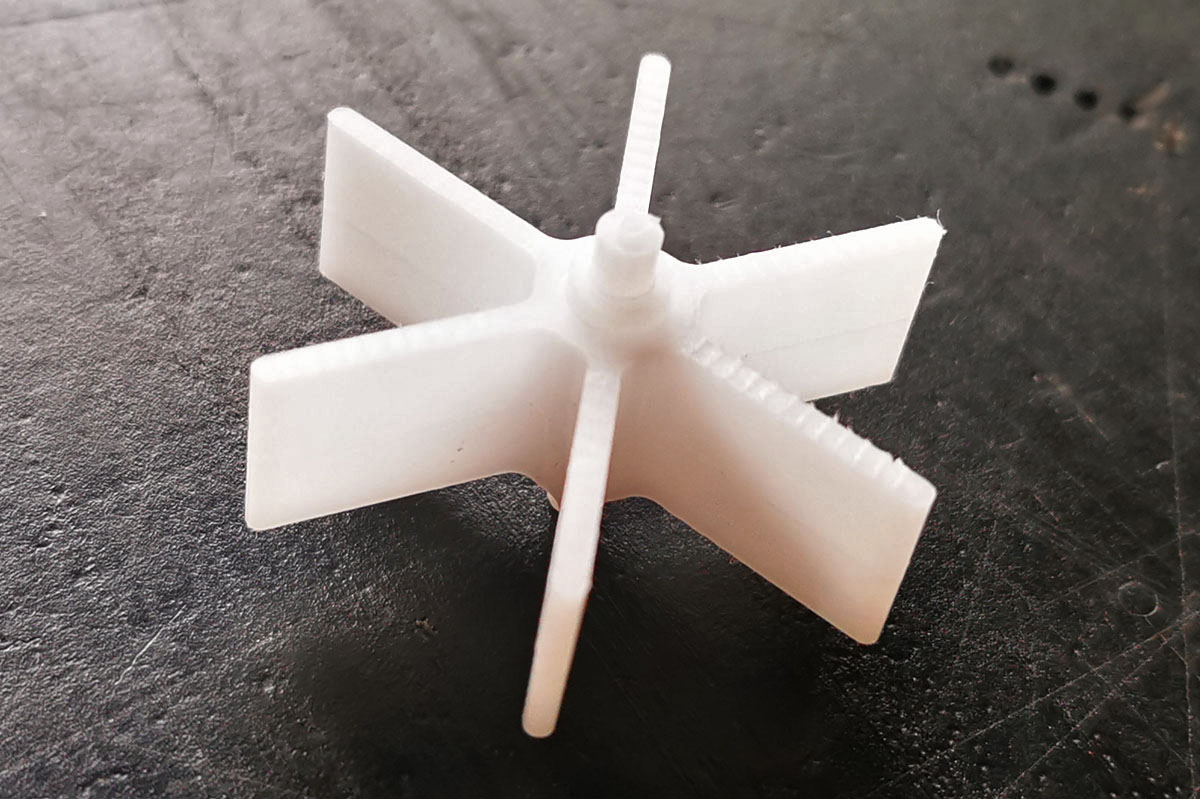

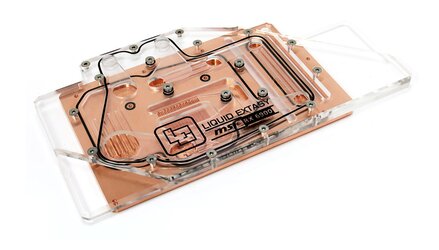

The spindlewatercoolingproject is finish and it works fine so far J

For small benchsession, i build an external watercooling. Compnents r Ehaim 1046, 120mm Radiator, 230V fan, filtresystem with valve of aquacomputer and a display to cherck the temperature. The system has a small size. 220x145x255mm. Coolingpower straight 200W. Peak 400W für some minuites.

For small benchsession, i build an external watercooling. Compnents r Ehaim 1046, 120mm Radiator, 230V fan, filtresystem with valve of aquacomputer and a display to cherck the temperature. The system has a small size. 220x145x255mm. Coolingpower straight 200W. Peak 400W für some minuites.