- Joined

- Dec 9, 2009

- Location

- Canada

Cute

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

Cute

Looking great man. Many people can start to build a from scratch case... few make it look good. Yours looks promising.

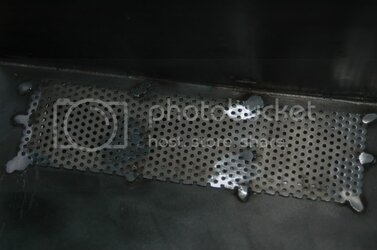

i am in love with that mesh i/o plate! that is sick, might have a go at one of them for myself, looking good with the rest of the project though, sub'd.

Just be careful when mounting a waterblock to that motherboard, their are a lot of ICs on the bottom of the board. Make sure you have some rubber grommet washers to make the back plate rest above those components on the back.

Love that backplate!

I haven't checked in lately, but now that I looked again, this is insane! Very nice build. It's sleek, it's small and most importantly powerful. Great craftsmanship!

I haven't checked in lately, but now that I looked again, this is insane! Very nice build. It's sleek, it's small and most importantly powerful. Great craftsmanship!Very cool build, I wish I had the tools to do something along these lines. Following this one to see the final product.

I haven't checked in lately, but now that I looked again, this is insane! Very nice build. It's sleek, it's small and most importantly powerful. Great craftsmanship!

I'll definitely check in more often.

I'll definitely check in more often.I'll definitely check in more often.

Perhaps a 45-degree adapter + one of those triple rotary fittings? That's a really tight space though; not sure if it would be the right angle or not.