- Joined

- Jul 10, 2010

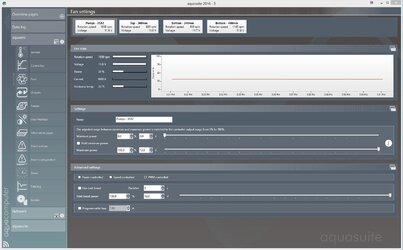

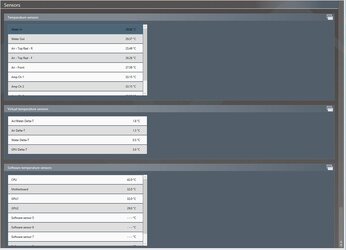

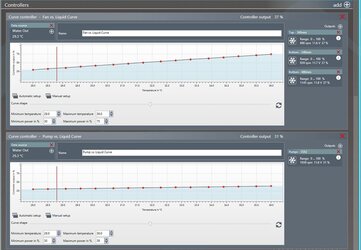

After having TWO Lamptron fan controllers fail on me, i've been considering picking up an Aquacooler aquaero. I know some people here have experience with this controller, so i was hoping you could help me plan out my purchase before I start throwing money around.

First off, i can run 9 thermaltake riing fans (.2a, 2.4 watts) off of 1 fan port without dealing with a poweradjust expansion, correct? I ask to make sure i'm not doing my math wrong, my old fan controller claims it can handle 30 watts, yet i burned through two units running 21.9w of fannage.

I'm also a bit confused on the best way to run a D5 pump on this controller. I know AquaComputer has a D5 designed to work with their system, but it's double the price of a normal d5. I want to have some degree of monitoring for pump failure through their software, but i know my existing 2 pin molex powered pump won't suffice. Can i use a non-AquaComputer D5? Can the D5 be powered directly through the aquaero controller? (or does it even need to be)

I was also curious if anyone has any experience running filters in their loops? I know it's generally ill advised, since it has the potential to add a lot of restriction to your loop, and if you need a filter, you likely have other problems you should be addressing. However, those of you who have seen my buildlog know that i've had some issues with some contaminants in my loop causing damage to multiple gpu waterblocks, a pump, and almost all of my fittings. That's probably around $400 in compromised equipment in total.

I believe I have removed all of the questionable components, and contaminants, but i just installed a new gpu/gpu block, new hardline, and a replacement pump from the oc classifieds section, so at this point I can't be too safe. I noticed aquacomputer has a nice looking unit specifically designed for pc loops. Can you think of any reason i shouldn't pick one up for my loop?

Thanks for the help guys!

First off, i can run 9 thermaltake riing fans (.2a, 2.4 watts) off of 1 fan port without dealing with a poweradjust expansion, correct? I ask to make sure i'm not doing my math wrong, my old fan controller claims it can handle 30 watts, yet i burned through two units running 21.9w of fannage.

I'm also a bit confused on the best way to run a D5 pump on this controller. I know AquaComputer has a D5 designed to work with their system, but it's double the price of a normal d5. I want to have some degree of monitoring for pump failure through their software, but i know my existing 2 pin molex powered pump won't suffice. Can i use a non-AquaComputer D5? Can the D5 be powered directly through the aquaero controller? (or does it even need to be)

I was also curious if anyone has any experience running filters in their loops? I know it's generally ill advised, since it has the potential to add a lot of restriction to your loop, and if you need a filter, you likely have other problems you should be addressing. However, those of you who have seen my buildlog know that i've had some issues with some contaminants in my loop causing damage to multiple gpu waterblocks, a pump, and almost all of my fittings. That's probably around $400 in compromised equipment in total.

I believe I have removed all of the questionable components, and contaminants, but i just installed a new gpu/gpu block, new hardline, and a replacement pump from the oc classifieds section, so at this point I can't be too safe. I noticed aquacomputer has a nice looking unit specifically designed for pc loops. Can you think of any reason i shouldn't pick one up for my loop?

Thanks for the help guys!