I wouldn't question quality of an EK+Asus partnership!

Never assume any components are 100% OK which involve seals that can possibly leak and that have the ability to cause $$$ worth of damage in an instant.

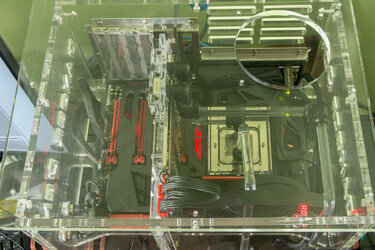

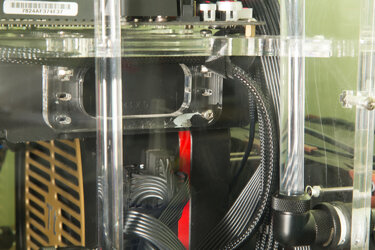

Pull the VRM block off (top only - black screws) and verify that the o-ring is seated correctly.

It may have simply popped out of its seat and then squashed during the assembly phase.

I have been using a Formula VIII board for over a year now with a similar setup as the VII and the VRM block is still working OK under fluid - You probably were just unlucky and received the dreaded 'one-off' faulty unit.

Lucky that it did not cause any permanent damage.

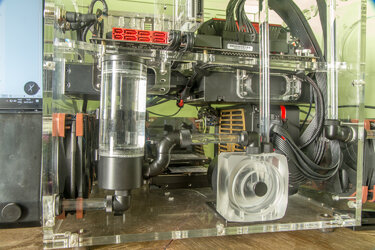

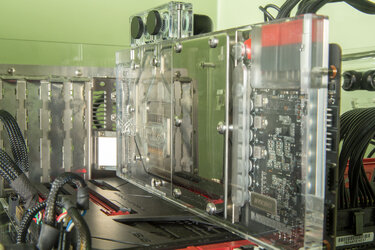

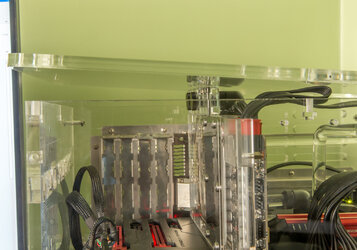

In the future think about possibly assembling an air pressure tester such as the ones below that I knocked up. You simply screw one of these into an open G1/4" port and seal the rest of the loop. You then pump the loop up to around 10 PSI (with a bike pump) and monitor for a short while (30 mins to an hour or so is plenty with this setup). Any major/minor leaks will show up us a drop in air pressure on the gauge.

Easy as to test before you fill a loop up with no danger of coolant leaking over electronics...!

Last edited: