- Joined

- Dec 10, 2011

- Location

- Cádiz (Spain)

Wow. Three of those beasts!!

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

Wow. Three of those beasts!!

Very nice!

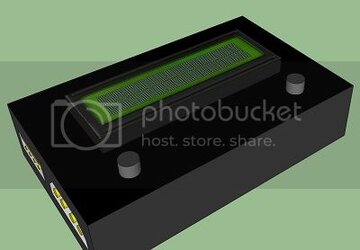

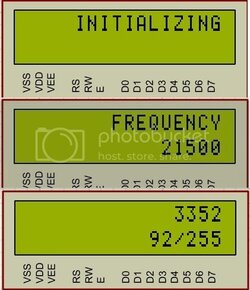

The controls are similar to my pushbutton two-channel controller, though mine lacks a display screen (having that is a nice feature!).

Please keep us updated, I want to see it as it happens!

Yeah, really nice renders. I suck at making things pretty like that.

Good luck with your proyect.

Good luck on the patents, I have posts for a multi-frequency PWM fan controller here on OCF from last year, prior art on that one.

That's what publishing and prior art is for, but yeah it's a screwed up system.