- Joined

- Jan 31, 2024

- Location

- Gulf Breeze, FL

- Thread Starter

- #21

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

Yeah, I did a lot of research on the stuff and I could find no negative feedback. It's been on the market for over a decade so I decided the risk was fairly low. Rated to 500 psi so it must be pretty stout. Crosses fingers...I will be very interested to hear about the copper glue (saw your posts on another forum) works out.

As an ex-HVAC mechanic, not using sil-fos, solder, or brass ring compression fittings where needed is just a call-back waiting to happen. lol

Ohhhhh I've dreamed of doing this! I LOVE the look of copper so this has me practically drooling lolNow I get to take it all back apart to re-polish and clear coat.I was thinking last night that with some garden hose and worm clamps this could have been finished two days ago...

View attachment 365058 View attachment 365057

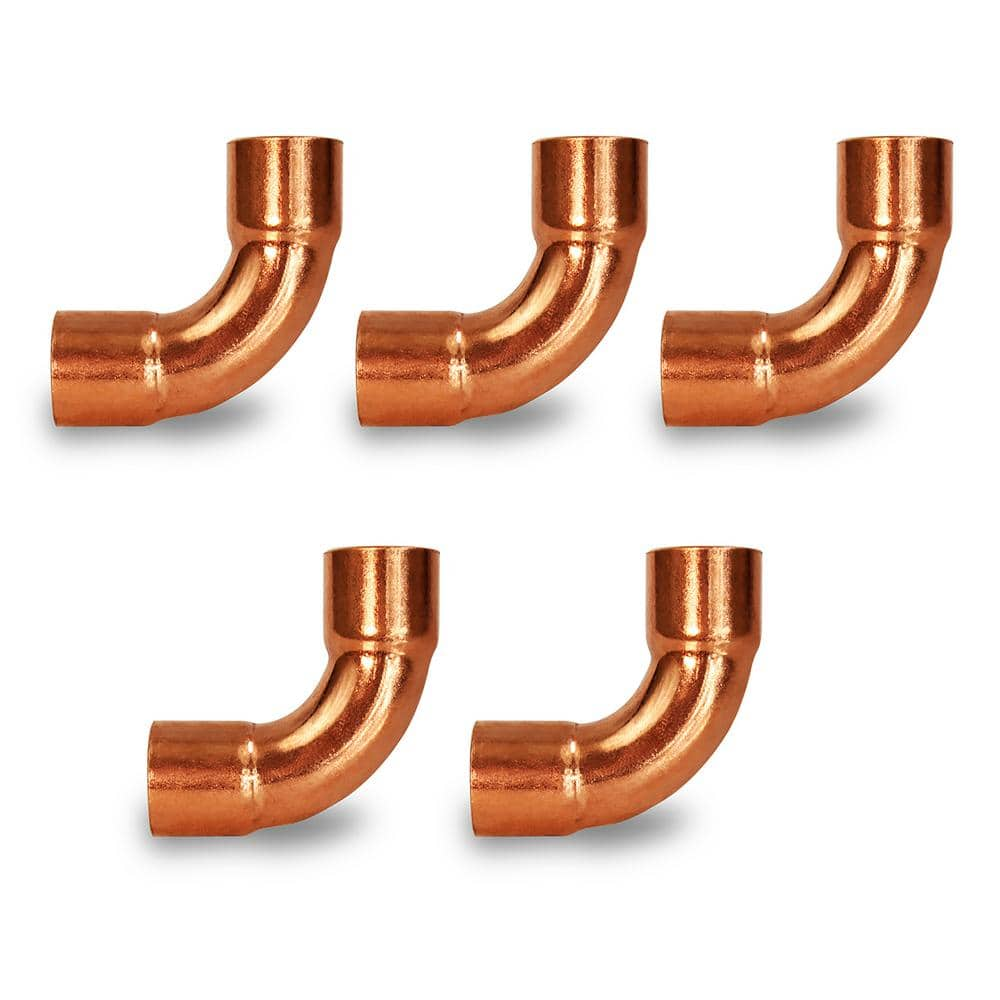

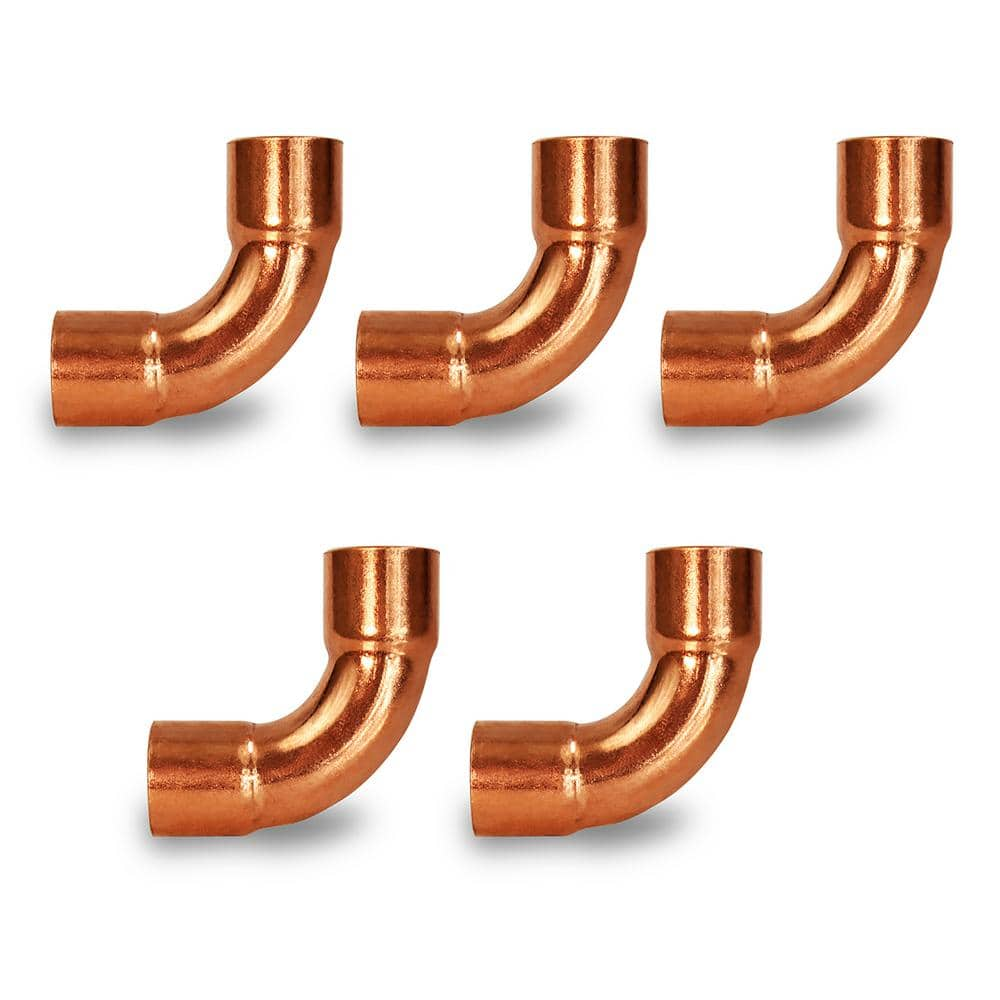

If you decide to rebuild the loop, consider long radius 90's. Reduces loop pressure drop over a short radius 90 & looks kinda cool (IMHO).I already want to change a couple of things about the loop, but I'll leave it be for a spell.

Yes, standard box store copper tubing and fittings. This is what I used... https://www.ebay.com/itm/2333510168...d0LDO6_bOHa8lLl8DinIy_fidB_C1oERoCrOcQAvD_BwE Rated for up to 500 psi.Ohhhhh I've dreamed of doing this! I LOVE the look of copper so this has me practically drooling lol

Did you solder those fittings or glue them maybe? They look like typical copper solder fittings correct?

Yes, they do. There is also a compression variety out there with distinctive ridges that I really liked the looks of...could probably solder or glue them as well. https://www.ferguson.com/product/ni...s-coupling-(less-stop)-npc601ldd/3033922.htmlIf you decide to rebuild the loop, consider long radius 90's. Reduces loop pressure drop over a short radius 90 & looks kinda cool (IMHO).

The Plumber's Choice 1/2 in. Copper C x C Long Radius 90-Degree Elbow Fitting with 2-Solder Cups (5-Pack) 0012CCLT-5 - The Home Depot

The Plumber's Choice is proud to serve all your plumbing needs with exceptional service, quality and variety. We feature a broad line of pipe fittings, available in various styles and sizes, to satisfywww.homedepot.com

You got me thinking about those fittings. I wonder how much pressure those internal o-rings would hold without any compression or glue? I have not had one in hand to judge the fit, but we are relying on simple o-rings on our termination fittings already and they don't leak. How easy and adjustable could a loop be if it actually worked?You can't solder ProPress fittings, but you could probably glue them. Long radius ProPress 90 elbow...

Oof. Man there are some old people here.Paint will resize...

I have seen that cooler before its fanless right?This actually my second build with the MSI Project Zero motherboard. Below is a pic of my daily driver with a 8700G which is semi-passively cooled with a Noctua P1. I will likely never build another pc that doesn't take advantage of back connector motherboards...I just hate all those janky looking cables. Hoping one day integrated graphics get good enough to do away with the fugly gpu in the game rig as well.

View attachment 365050

She be chillin...

View attachment 365051

Yes, fanless.I have seen that cooler before its fanless right?