Please help!

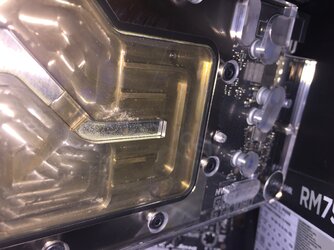

I've had my first loop running for less than a year, and I just noticed that there is some color changes to the tubes and there is corrosion or growth present in the GPU block. I have very limited experience in this, so I don't really trust my own judgment here. Could someone please help me understand if this is corrosion or growth and identify the perpetrator?

I don't really care how it looks, I just want a healthy loop.

1st picture: Clear tube new and the yellow tube is an example of the tubes in the loop.

2-4 pictures: From the GPU block.

Setup:

EK - Ekoolant EVO - CLEAR

EK - ACF Fitting - 13/10mm - Black

EK - Supremacy EVO - Full Nickel (Original CSQ)

EK - RES X3 110

EK - CoolStream SE 360 (Triple)

EK - Koppling - Plugg G1/4

EKWB EK-FC1080 GTX Nickel GPU Block

MasterKleer - 13/10mm CLEAR

Innovatek HPPS Plus - 12V Pump

Thread adapter kit G1/4for Innovatek HPPS Pl

I've had my first loop running for less than a year, and I just noticed that there is some color changes to the tubes and there is corrosion or growth present in the GPU block. I have very limited experience in this, so I don't really trust my own judgment here. Could someone please help me understand if this is corrosion or growth and identify the perpetrator?

I don't really care how it looks, I just want a healthy loop.

1st picture: Clear tube new and the yellow tube is an example of the tubes in the loop.

2-4 pictures: From the GPU block.

Setup:

EK - Ekoolant EVO - CLEAR

EK - ACF Fitting - 13/10mm - Black

EK - Supremacy EVO - Full Nickel (Original CSQ)

EK - RES X3 110

EK - CoolStream SE 360 (Triple)

EK - Koppling - Plugg G1/4

EKWB EK-FC1080 GTX Nickel GPU Block

MasterKleer - 13/10mm CLEAR

Innovatek HPPS Plus - 12V Pump

Thread adapter kit G1/4for Innovatek HPPS Pl

Attachments

Last edited: