Hi,

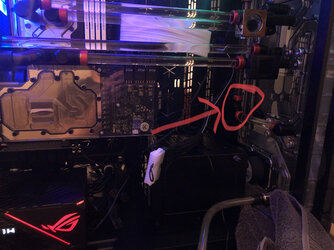

IÂ’m making my first hard tube loop and during my initial leak test the loop failed at the point in the photo - the bottom of the L fell open an the water drained down onto the towels - it scared the crap out of me but not much harm done

I then took that part apart and sanded down the tube and put the connector on again with fresh O-ring as tight as possible - I just wonder why it happened and is this a bad design on my part and is that portion inherently risky? Any advice? Is it because itÂ’s hanging?

itÂ’s now been leak testing for an hour and seems ok

IÂ’m making my first hard tube loop and during my initial leak test the loop failed at the point in the photo - the bottom of the L fell open an the water drained down onto the towels - it scared the crap out of me but not much harm done

I then took that part apart and sanded down the tube and put the connector on again with fresh O-ring as tight as possible - I just wonder why it happened and is this a bad design on my part and is that portion inherently risky? Any advice? Is it because itÂ’s hanging?

itÂ’s now been leak testing for an hour and seems ok