Erm... you just basically took every point on my pot that is different from a typical design, and said it's bad.

(I'm not trying to step on your toes, I'm just stating my POV and reasons. I appreciate input, even if it directly contredicts my entire design.

)

1. Aluminum instead of copper

2. Not using threads to seal. (I'm using a shrink-fit., It's permanent but will never leak)

3. Aluminum tube (Not much of an issue though, not intended for LN2, only dice dust should contact the tube)

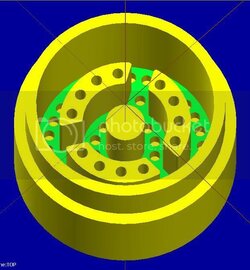

4. "Moderate Mass" as for as ln2 pots go... I'm making an extremely light pot... with a ton of surface area for it's size)

5. The mounting mechanism is uhh... going to be about 1.5" above the processor. There's no other way to do it with the materials I've got on my desk.

So, Let me expound:

1.

Aluminum is ~1/3 the density of copper, and has ~60-80% the thermal conductivity of copper (For typical alloys)

The

material cost for my dry ice pot will be about $3 for each base. If I purchased copper from online metals it would be $50 for each base. (Less Shipping!)

I can get copper, In fact I have about 25 pounds of it on my desk. I can even get it from the same place I'm buying my aluminum from. (Likely for less than online metals' prices)

I'm not convinced that an aluminum dry ice pot will be significantly outperformed by a copper one.

I reached -70C on my first try. (And my new design is totally different, for the better I think)

Also the thermocouple probe had about 1 1/4" of aluminum between it and the cavity, with just plain ice(i mean H2O) it registered ~5 C or something.(no pics) (No load)

(I had to work my way up to dice, plus I had to wait for someone to come back from the store with acetone

)

2.

I Don't have a lathe, only a CNC mill. I would have to threadmill my parts to make threads (or get a 3" tap and die... no)

A Srink fit isn't too hard to assemble, just heat/cool the parts and slide them together. + my 1/8" tube wall isn't an issue (otherwise I need bigger material and thicker walls)

3.

It's intended for dice.

I would consider Acetal for the brackets/tube If I was considering making a copper pot for ln2.

4.

At .3 LBS this is an extremely light base, and it will be lighter when I finish the design.

It is my intention that this pot never run out of dice, the main cavity is designed to be able ot mix well with dice and acetone, the temp should reach it's point and stay there as long as the pot is topped off.

(Dice, It's not LN2 where you add X ammount every so often, you just keep it full.)

5.

My tube OD is the same as my stock OD, the only way to get a bracket on is to put it between the two... Saves $2 on allthread?

If I make an acetal top, I'll probably do the bracketing differently.

I don't see how frost is such an issue though, I ran for 3-4 hours on my dice run and the worse of it was the frost at the very top, there wasn't anything inside of my insulation, or near the processor socket. (but since everything is coated with jelly, It wouldn't matter if there was.)