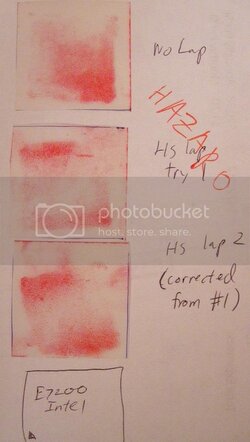

Pressure mount testing with TRUE:

Ambient = Constant 21C

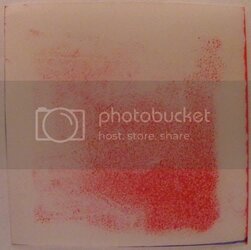

TRUE not lapped:

1.272V idle

380x9

41/39C idle

---

1.220V load

380x9

58/58C load

==============

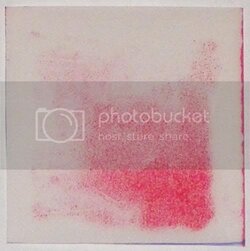

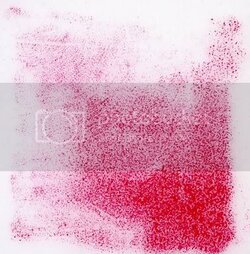

TRUE lapped (TRY 2 NUMBERS, #1 I did not test):

1.272V idle

380x9

36/34C idle

---

1.220V load

380x9

54/54C load

It doesn't look like temps should of dropped, but they did...

Hopefully you can shed some insight?

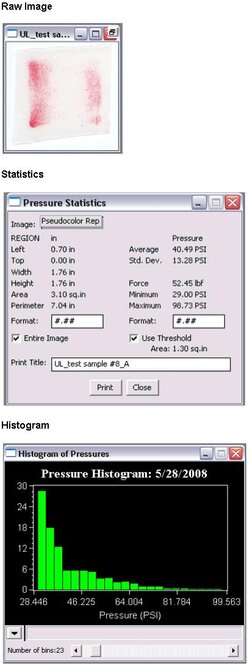

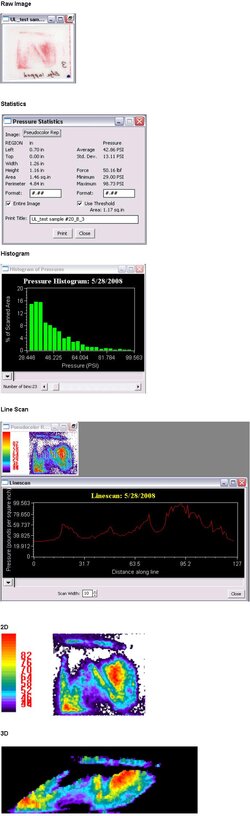

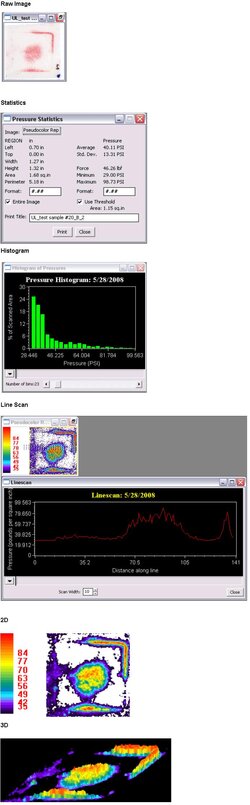

Looks like you have one of the highest pressures to date, hard to tell from the pictures, have to wait for the analysis.

With good pressure you may gain a degree or so 40lbs-80lbs. With changes in the contact area + good pressure you can swing several deg. obviously.

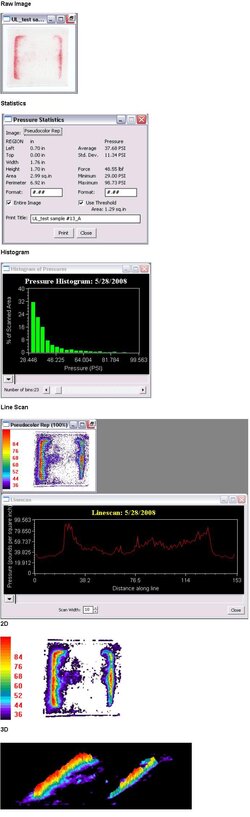

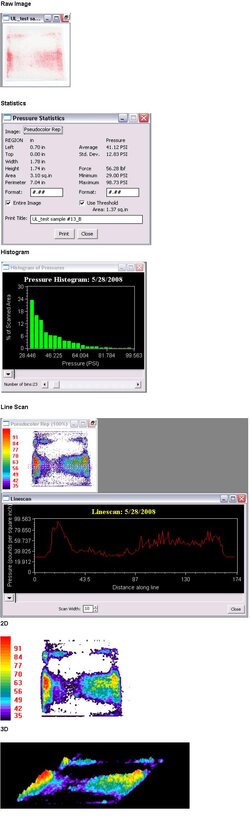

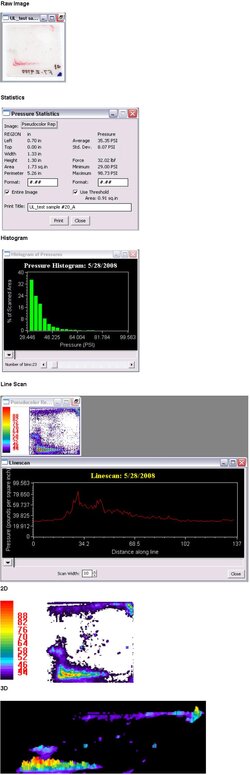

First pic the pressure/contact looks biased lower right with about 1/2 the IHS with lighter pressure. which can give a higher temp. Not knowing how the cores are oriented to the pressure imprint you could be light on one of the cores or possibly one side of both.

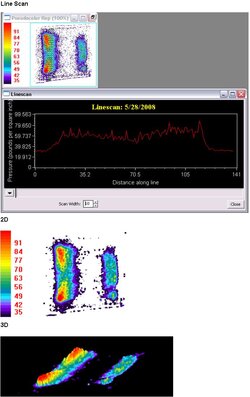

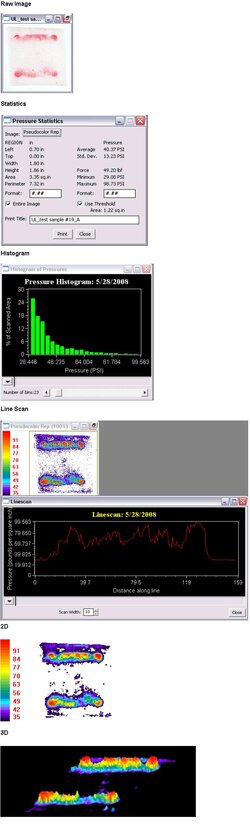

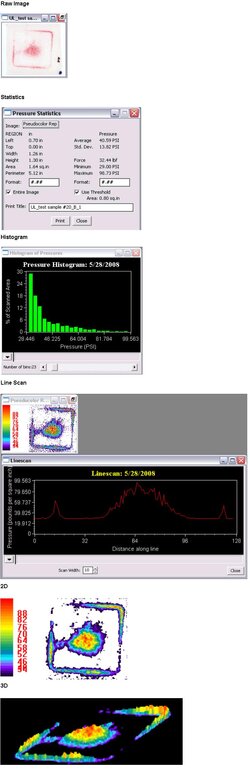

On the second one you look light in the center with the load on the top and bottom edges.

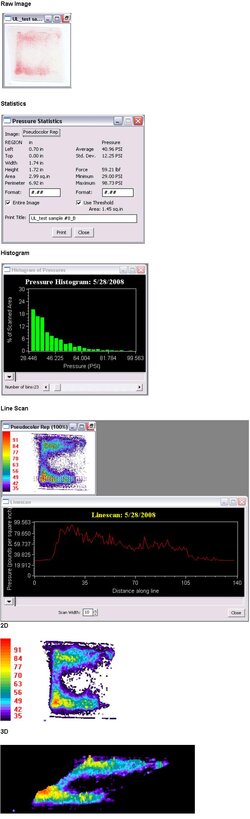

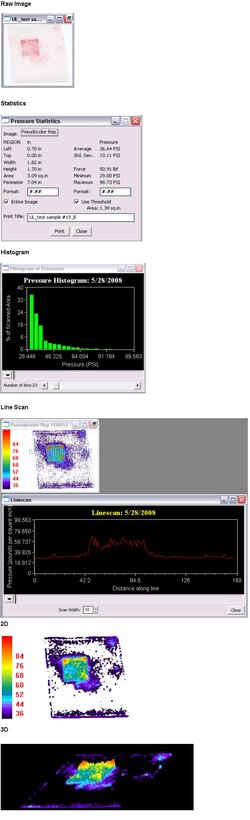

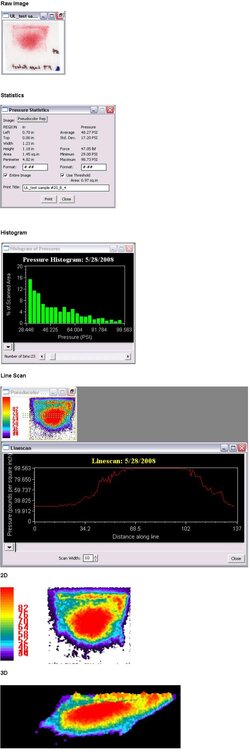

The third pic look like an almost perfect distribution on load combined with a good pressure reading.

The one thing the film does not tell you is the depth on the "white" areas. You could be .001 or one mile the only indicator being a well defined contact area.

The paste resolves to about .001 thick in the contact areas so if you have a low spot .001-.002 The paste in those low areas would be .002-.003 thick which would affect performance in those Low spots.

Down at these .001 levels details become magnified - if your hardware is off a few thousands on one side will probably bias loads. Another thought I had was the IHS is still sheet metal and with 50-60lbs does it flex or ripple a few thousandths under load? On some of the results I have seen 90+ lbs on some spots. Maybe you will still get a variance between two good lap jobs with different flex/hardware? I do not know just speculating.

I was thinking that a poor man's test could be something like this. Lightly oil/wax? you sink base and then apply some 5min epoxy to the IHS, clamp toghether, Let harden and then separate. The sink should lift off with no problem and what sticks to your IHS would be your low spots which could then be lapped until there is no more epoxy, at which point you would know you are flat.

You could then reverse the process for the sink. I am not entirely sure about it I am still thinking that it through, maybe superglue? Elmer's glue?some kind of liquid plastic?