- Joined

- Dec 18, 2018

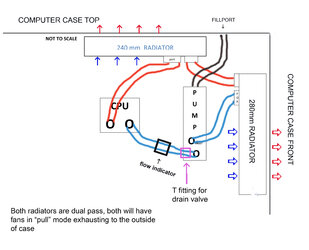

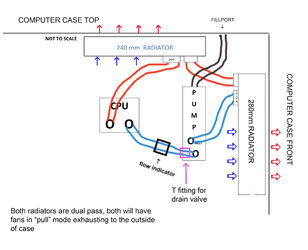

BELOW IS a cocktail napkin sketch of the radiator layout i'm getting ready to assemble

any suggestions, opinions etc i'd appreciate.

I would have preferred to go with one 360mm radiator in the roof of the case but that presented fitment issues with the rear exhaust fan and the front 5.25" external bay at the front top of the case, and that bay is needed

fans will be mounted on the radiator in "Pull" mode, exhausting to the outside of the case, and there will be 4 & 1/2 fans blowing in (i say 1/2 fan as it will be a 120 x 15mm fan turning low rpms - but point is the case will have good airflow with positive air pressure

What was the rear exhaust fan will be turned around to blowing inward, and i'm fabricating a shroud to direct it's airflow onto the motherboard

- - - Auto-Merged Double Post - - -

not sure why it posted the image twice, sorry about that

any suggestions, opinions etc i'd appreciate.

I would have preferred to go with one 360mm radiator in the roof of the case but that presented fitment issues with the rear exhaust fan and the front 5.25" external bay at the front top of the case, and that bay is needed

fans will be mounted on the radiator in "Pull" mode, exhausting to the outside of the case, and there will be 4 & 1/2 fans blowing in (i say 1/2 fan as it will be a 120 x 15mm fan turning low rpms - but point is the case will have good airflow with positive air pressure

What was the rear exhaust fan will be turned around to blowing inward, and i'm fabricating a shroud to direct it's airflow onto the motherboard

- - - Auto-Merged Double Post - - -

not sure why it posted the image twice, sorry about that