- Joined

- Sep 7, 2013

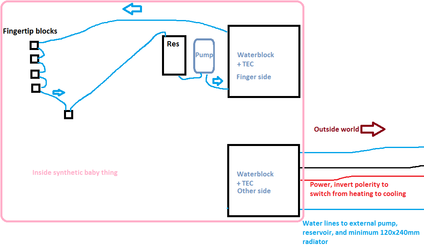

ok, so the water heats the hot side, and the fan cools the cold side?

Or are you trying to cool off both sides?

Or are you trying to cool off both sides?

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

That fan and heatsink are about right for cooling a ~15w load at most, possibly less.

You won't be cooling the water with it at any great rate.

Your best bet using that fan/heatsink would be to run ~7.5 to 10w of electrical power through the TEC, in turn pulling 7.5-5w of heat out of the water.

The issue with that plan though is that the water pump may well use the water for cooling, and if it does it'll be putting more heat into the water than the TEC is pulling out.

Even if it's not, 7.5w of cooling isn't going to get the water very far under ambient. Not without a tremendous amount of insulation on all the hoses and WB and such.

If you want to move a decent amount of heat out of the water via the TEC you're going to need a heatsink more along these lines:

View attachment 147860

Big.

You can do some thermodynamics equations with the surface area of your loop and the thermal conductivity of all the bits in it to figure out how many degrees below ambient a given amount of heat removal will give you. I do not know these calculations, but I know they exist.

My experience has been that with a TEC you need a lot of cooling on the hot side if you want to cool things off.

If you aren't aiming to get the cold side as cold as possible (which you're not) you're going to need exact control over the power draw. This is not something that diodes in series can give you. You need active control.

What I would do is use a microcontroller with a differential ADC and PWM outputs.

First regulate the voltage (active regulation, not diodes in series) being applied to the TEC to its max rated spec. No more.

Most 40x40mm TECs are rated for 15v, feel free to use the "raw" 12v out of a computer PSU. That'll be fine. Key is, it must be equal to or lower than the TEC's rated voltage, and it must not change in a meaningful way with load. This is where diodes fail for regulation, their voltage drop changes significantly with load.

Put a 0.1 ohm resistor in series with the TEC. Put a 10-47µF capacitor in parallel with that resistor.

Wire the microcontroller's ADC in parallel as well, - side to the TEC side of the resistor/cap, + side to the power supply side of the resistor/cap.

This, plus ohms law, gives you the average current flowing through the resistor, and hence the current flowing through the tec.

Combined with the active voltage regulation you can now calculate the wattage.

The microcontroller can PWM the ground side of the TEC (via MOSFET) for current/wattage control.

If you don't have access to a MCU with a differential ADC you can either buy a differential ADC chip that speaks i2c or SPI and have the microcontroller talk to that, or buy an op-amp and wire it to amplify the voltage across that resistor and give it a ground reference.

How hot is the air heatsink getting?

If it's not hot to the touch more cooling on the TEC hot side will not change the cooling rate of the TEC.

Given decent hot side temps, only more wattage through the TEC will increase cooling power.

If you're running a 130w 12V TEC at full power, that is about 65w of cooling, or ~221BTU/hr of energy transfer.

One BTU is the amount of energy it takes to heat or cool one gallon of water by 1°F.

So in theory you could cool one gallon of water by 3.68°F per minute.

Running that same TEC at 5V results in ~11 watts of cooling, or 37.x BTU/hr and less than a degree per minute per gallon.

More tec power is probably the answer then. Start cranking the voltage up and see what happens. Do be sure to stay under the maximum voltage rating of the tec of course.

If you give the tec Umax voltage it will draw Imax current, resulting in Qmax watts.

That, of course, assumes all the numbers are real.