I am sorry for the lack of recent updates - with the case more or less completed I've been spending a lot of my time overclocking the stuff inside of it

.

Some bad news - due to a completely random leak, my Mach II has died before I even got to properly implement it. However, I am mailing it to Gkiing of Xtremesystems for a repair and total overhaul. It looks like I'll be having the heavily modified and tweaked out Uber Mach II unit that this project originally called for after all... such is fate

.

I am having the unit:

~ Repaired

~ Reinsulated

~ Regassed with R507 (Unfortunately Gkiing does not have access to small amounts of R402 - R507 is slightly worse than R402 for temperatures as I mentioned way back in the project outlines, but is still a very signifigant improvement over R134

)

~ Captube replacement

~ Much larger condensor installed

~ chilly1 evaporator installed for easier mounting

~ More flexible and durable flex-line installed

My two goals with these modifications are greater ease of use for frequent evap mounts and removals, as well as a much higher heatload capacity to futureproof the unit.

For a dual-core processor down the road, or even for the next generation of processors way down the road, a high heatload capacity will be essential if this unit is to stay useful. The compressor is sufficiently powerful to handle a very hot processor, the charge just needs to be properly tweaked for capacity. Temperatures will intentionally be compromised slightly in order to accomplish this - the modified unit will provide slightly better temperatures than a stock Mach II, but at a

MUCH higher heatload capacity. My philosophy on this is that ~5 degrees celcius isn't going to accomplish much when you're already running at, say, around -40 degrees celcius; -40C with 240W of capacity is much more useful to me than -45C with 190W of capacity. These numbers are entirely innaccurate and for example only - I will have specific numbers as soon as the unit gets to British Columbia.

All of that said, I have a major update - the Big Black Beast now has peltiered GPU watercooling.

pwnt by pat

Get that radiator in there since you have it and all now....

fool

Who's a fool!? Watch your step brar'

The radiator/shrouds are my dream setup - this thing is fittingly a beast and a half of a radiator. Specifically for the Big Black beast project, Pwnt by Pat made me two custom fibreglass shrouds for a Fedco 2-342 single pass radiator, which (according to the plan) is now cooling a 172W peltier on my video card. Pat has put a lot of effort and workmanship into these shrouds - and the result is fantastic.

The custom radiator and the rest of the "Hotblack Watercooling" (the name will make sense in a minute

) is now installed and operational.

Let's take a look at the specifics of the watercooling circuit I've put together.

The pump I am using is a 12V Swiftech MCP600, my favourite waterpump for its low noise, great pressure, small size, and 12V operation. For the video card I am using a Danger Den Maze4-1 waterblock, with a 172W/24V peltier. The Peltier PSU I am using is a 24V/240W Meanwell unit. The Radiator is Pat's beastly Fedco 2-342 single pass radiator - low restriction, excellent heat capacity, and room for four 120mm fans with the fibreglass shrouds.

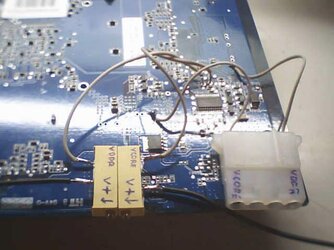

Here are the parts layed out:

. You see, I can easily make a window cutout in the door, but can think of no way to mount the plexi inside of the door without making the door too thick. As it is, the switches on one of my Rheos is touching the back of the door panel.

. You see, I can easily make a window cutout in the door, but can think of no way to mount the plexi inside of the door without making the door too thick. As it is, the switches on one of my Rheos is touching the back of the door panel.