-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why do they still use electrolytic caps?

- Thread starter magellan

- Start date

- Joined

- Feb 13, 2010

- Location

- Missouri

Exactly.$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

- Joined

- Sep 7, 2013

- Joined

- Jun 28, 2012

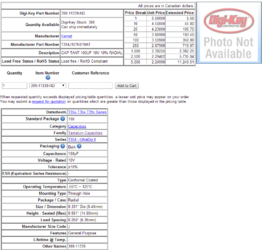

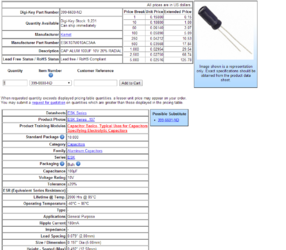

Solid state capacitors are more than 10x the cost of electrolytic capacitors (See Silver's pictures).

Multiply that by 10-20 per GPU and 50+ per motherboard, that cuts cost fast.

Its not "being cheap", its "not making a motherboard cost $700".

Multiply that by 10-20 per GPU and 50+ per motherboard, that cuts cost fast.

Its not "being cheap", its "not making a motherboard cost $700".

- Joined

- Dec 1, 2007

- Location

- Near Toronto Canada

Solid state capacitors are more than 10x the cost of electrolytic capacitors (See Silver's pictures).

Multiply that by 10-20 per GPU and 50+ per motherboard, that cuts cost fast.

Its not "being cheap", its "not making a motherboard cost $700".

You mostly find electrolytic caps in "rock bottom ronnie" segment and OEM motherboards, as well as audio applications these days. The days of buying a midrange board and seeing it coated in electrolytic caps are over.

- Joined

- Jun 28, 2012

You mostly find electrolytic caps in "rock bottom ronnie" segment and OEM motherboards, as well as audio applications these days. The days of buying a midrange board and seeing it coated in electrolytic caps are over.

There's no doubt that we see less electrolytic caps than we used to, especially for mission-critical portions of the motherboard.

But almost all boards still have a fair amount of them.

- Joined

- Jul 20, 2002

- Thread Starter

- #8

Can electrolytic caps be made as reliable as tantalum caps? I remember reading an article (maybe posted by ED) that suggested the huge number of electrolytic cap failures in the early 21st century were due to Taiwanese based industrial espionage that failed to properly copy the complete formula for some revolutionary Japanese electrolyte formula.

- Joined

- Sep 7, 2013

Yes, don't use stolen recipes!Can electrolytic caps be made as reliable as tantalum caps? I remember reading an article (maybe posted by ED) that suggested the huge number of electrolytic cap failures in the early 21st century were due to Taiwanese based industrial espionage that failed to properly copy the complete formula for some revolutionary Japanese electrolyte formula.

My board has all Japanese Solid Capacitors.

Naw seriously. ^ This.

My boards has all solid caps as well.

They aren't electrolytic, so they won't explode.

- Joined

- Sep 7, 2013

Actually, I've read that tantalum caps can explode.

Yes, but I was referring to the Solid Capacitors on most good motherboards

- Joined

- Sep 7, 2013

Wanna see what happens when a cap explodes while you're baking a vid card?

huh..

Bucket list

----------

✓ "Watch GPU explode in oven"

Too hot?

I was under the assumption that those solid caps won't explode?

- Joined

- Jul 14, 2002

Wet tantalum caps are electrolytics. Even solid polymer caps, whether tantalum or aluminum, are electrolytics, according to the company that invented them: "Low ESR obtained by using conductive polymer electrolyte."Can electrolytic caps be made as reliable as tantalum caps? I remember reading an article (maybe posted by ED) that suggested the huge number of electrolytic cap failures in the early 21st century were due to Taiwanese based industrial espionage that failed to properly copy the complete formula for some revolutionary Japanese electrolyte formula.

I believe wet tantalums were preferred because they could pack more capacitance in the same amount of space, and they had lower ESR, but apparently developments in aluminum caps have largely nullified those advantages, especiailly for ESR. Also tantalum caps cost more and are apparently more vulnerable to being destroyed when exposed to excessive voltage.

I believe solid polymer caps have lower ESR at frequencies above about 20,000 Hz.

The capacitor scandal that started about 12 years ago was caused by the use of inferior electrolytes and probably aluminum foil contaminated by too much copper. OTOH the high failure rate of Japanese Nichicon models HM and HN caps from around 2002-2004 was probably due to something else, maybe too much electrolyte. Those Nichicons were fixed by 2005, and apparently the only Japanese caps that are still bad are the TK brand (Toshin Kogyo) and models KZG and KZJ from United Chemicon/Nippon Chemicon. Most cap brands from Taiwan, South Korea, and China are apparently still bad, with Jamicon maybe being one of the few good ones. Even Luminous Town, the Chinese company where the capacitor scandal started (their properly made electrolyte formula was stolen and reproduced incorrectly for other manufacturers), makes low ESR Ltec brand caps that don't seem to last that long. Solid polymer caps seem to have better track records, whether Japanese or not, but I haven't seen anybody do a comparison test of brands.

Last edited:

QUOTE:The solid capacitors are a newer design using organic semiconductors or OSCON. They couple low ESR (which is good) and a wider temperature stability range (since the solid capacitors can't/won't freeze or boil). They're significantly better than the garden variety capacitors in most respects - to compare, the maximum temperature the average liquid capacitor can handle is about 85-95 degrees, while the solid caps handle in excess of a hundred. They also have better characteristics in general, but I doubt anything that most users would notice.

- Joined

- May 30, 2004

Wanna see what happens when a cap explodes while you're baking a vid card?

Those caps look like FZs! Eww! They're cheap electrolytics that look like polymers!

Card was only in for 4 minutes @ 375f.huh..

Bucket list

----------

✓ "Watch GPU explode in oven"

Too hot?

I was under the assumption that those solid caps won't explode?

- Joined

- May 10, 2009

It's a combination of money, ESR, capacitance, resonate frequency, and size.

Electrolytic caps pack more capacitance into a given area than anything else, by a long shot. Their ESR is fairly high and their thermal resistance is also high. This means they have a fairly limited current handling ability.

"Polymer" "solid" caps are electrolytic as well, they just use a different electrolyte. They're also not especially solid. They have much better heat transfer and much lower ESR than standard electrolytics, but are much bulkier for a given capacitance and cost more.

Chip-type tantalum caps (like are used on GPUs), are very small for their capacitance (though still larger than electrolytics), have very good heat transfer abilities, fairly low ESR (not as low as polymers can get, but far lower than standard electrolytics), and cost a lot.

All of them can fail. Electrolytics typically leak conductive gunk when they got too hot (reverse polarity or over-voltage overheats them FAST). Polymers tend to fail silently or go POP (again, reverse polarity or over-voltage kills them quickly), tantalums are very difficult to kill unless you over-volt them or reverse polarity them, then they burst into flame and burn quite nicely.

EDIT:

I think you may have overbaked that card a little.

Electrolytic caps pack more capacitance into a given area than anything else, by a long shot. Their ESR is fairly high and their thermal resistance is also high. This means they have a fairly limited current handling ability.

"Polymer" "solid" caps are electrolytic as well, they just use a different electrolyte. They're also not especially solid. They have much better heat transfer and much lower ESR than standard electrolytics, but are much bulkier for a given capacitance and cost more.

Chip-type tantalum caps (like are used on GPUs), are very small for their capacitance (though still larger than electrolytics), have very good heat transfer abilities, fairly low ESR (not as low as polymers can get, but far lower than standard electrolytics), and cost a lot.

All of them can fail. Electrolytics typically leak conductive gunk when they got too hot (reverse polarity or over-voltage overheats them FAST). Polymers tend to fail silently or go POP (again, reverse polarity or over-voltage kills them quickly), tantalums are very difficult to kill unless you over-volt them or reverse polarity them, then they burst into flame and burn quite nicely.

EDIT:

I think you may have overbaked that card a little.

Last edited:

EDIT:

I think you may have overbaked that card a little.

But I just needed 1 more good run.