- Joined

- Jan 29, 2009

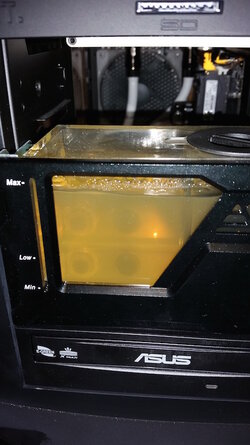

Silver needs hydrogen sulfide to tarnish possibly caused anerobic digestion.

Hydrogen sulfide results from the breakdown of organic matter.

If your water smells of sulfer then some organic contaminant has resided in your loop.

Silver can't tarnish from oxygen alone and hydrogen sulfide is formed in the absence of oxygen.

Edit: silver tests

No1 strong magnet e.g. Neodymium magnet - silver is paramagnetic (it shouldn't be attracted to the magnet due to it's low field.

No2 ice should begin to melt as if it's above room temperature due to silvers high conductivity.

Hydrogen sulfide results from the breakdown of organic matter.

If your water smells of sulfer then some organic contaminant has resided in your loop.

Silver can't tarnish from oxygen alone and hydrogen sulfide is formed in the absence of oxygen.

Edit: silver tests

No1 strong magnet e.g. Neodymium magnet - silver is paramagnetic (it shouldn't be attracted to the magnet due to it's low field.

No2 ice should begin to melt as if it's above room temperature due to silvers high conductivity.

Last edited: