- Thread Starter

- #61

Hi Witchdoctor!

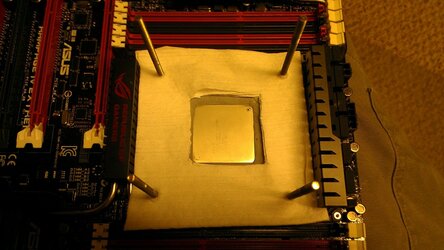

That looks identical to what I do for ss. I'll try to fill any gaps around the cpu then add the thin layer of eraser across the top of the holdown.

Still not entirely clear on the "Use electrical tape or even masking tape for sealing the CPU to the plastic socket" guidance, though.

That looks identical to what I do for ss. I'll try to fill any gaps around the cpu then add the thin layer of eraser across the top of the holdown.

Still not entirely clear on the "Use electrical tape or even masking tape for sealing the CPU to the plastic socket" guidance, though.