- Joined

- Mar 27, 2011

- Location

- Soviet Mexico

I don't know what people are using for boards these days, but I know a good chunk of the ASRock boards are now conformaled. Which is extremely helpful. Granted there are still places in sockets and slots that you can have condesnation problems but it certainly does help the prep process.

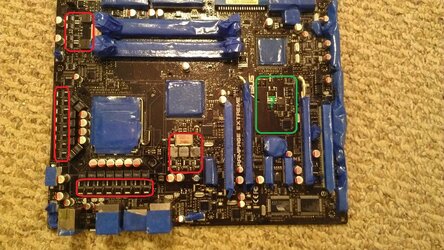

Big places you are gonna see creep and melt are Memory slots tend to get alot of creep from cold these days. The closer the socket is the memory the worse this tends to be. Small power phases for memory also tend get some creep and melt around them, most of the time these phases are good 2" or so away from the sockets. The main power phases don't get creep so much as they can melt the cold. Keep in mind aswell that you might want to identify the power phase controller chips ahead of time, for distance to socket, In some situations you might find it a requirement to heat these keeps to keep them stable and happy.

In situations where cold creep is a major problem try to avoid Eraser. Conformal or let are good for these situations. If your not comfortable doing that to a board, Use eraser sparingly as needed, than fill in with frostking/neoprene. Even if you use conformal you still want to use a certain degree of closed cell insuation, to act as a moisture barrier. this is extremely helpful around memory and around main VRM's.

even doing a good insulation job, your gonna need a good amount of fans, To blow warm/hot air to prevent cold creep into the memory and power phases. Since even neoprene gets cold enough over time to start to condense and frost up, Since you need multiple inches of coverage to really prevent icing, and thats not usually a luxury we have these days due to decreasing board sizes and component density.

Big places you are gonna see creep and melt are Memory slots tend to get alot of creep from cold these days. The closer the socket is the memory the worse this tends to be. Small power phases for memory also tend get some creep and melt around them, most of the time these phases are good 2" or so away from the sockets. The main power phases don't get creep so much as they can melt the cold. Keep in mind aswell that you might want to identify the power phase controller chips ahead of time, for distance to socket, In some situations you might find it a requirement to heat these keeps to keep them stable and happy.

In situations where cold creep is a major problem try to avoid Eraser. Conformal or let are good for these situations. If your not comfortable doing that to a board, Use eraser sparingly as needed, than fill in with frostking/neoprene. Even if you use conformal you still want to use a certain degree of closed cell insuation, to act as a moisture barrier. this is extremely helpful around memory and around main VRM's.

even doing a good insulation job, your gonna need a good amount of fans, To blow warm/hot air to prevent cold creep into the memory and power phases. Since even neoprene gets cold enough over time to start to condense and frost up, Since you need multiple inches of coverage to really prevent icing, and thats not usually a luxury we have these days due to decreasing board sizes and component density.

happy to help

happy to help