T=K, I'm also watching this thread closely, too bad I can't contribute too much cause now practically I have no time to sit down quitely and sketch the circuit for this purpose, and also I think this ain't simple circuit too.

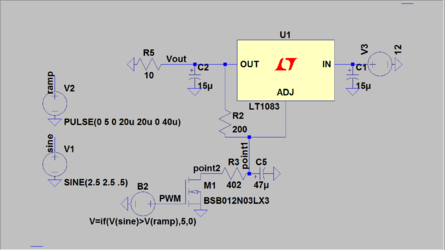

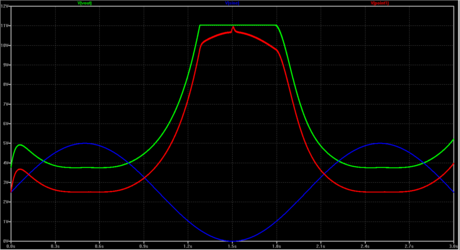

Imo, the pwm signal which is switching at 5 volt, it needs to be converted to pure DC with low pass filter first to have a clean signal free from those pwm frequency, and then this converted "clean & stable" voltage level will be acting as reference for the final fan output voltage.

Although this sounds simple, it needs further processing for the offset and gain before handling it to later power section, which could be plain-jane linear power regulator or more advance and complicated power switching controller.

I believe, this offset and gain level are like manual one time adjustment, probably to be implemented like sort of a pot or trimpot. This is crucial since we can not do direct translation like 0% to 100% duty cycle at the pwm signal to 0 - 12 volt.

Why ? Few scenarios I could think of ...

For example people want to hook this converter at the mobo's pwm header instead of pwm controller :

Example scenario :

Probably because of the bios/mobo built-in program limitation, the mobo pwm header can only producing somewhere like 25% when the cpu was idling and upto 85% duty cycle at fully loaded cpu, instead of pure 0-100%, this can creates complications such as :

The user wants that when at lowest 25% duty cyle, this converter will outputting lowest possible volt for the fan but still spinning, and while at 85%, this will translate to max 12 volt for max fan speed.

..or ..

At the same 25% duty cycle aka idling cpu, he wants the fan to be fully stopped to reduce the fan noise to zero, this alone is like setting the output to 0 volt, while at 85% dutycycle, its expected to drive the fan around 10 volt since the owner 'feels' it is the max tolerated speed.

Remember, when driving fan with voltage, different fans behave differently at low voltage, some will rotate at minimal speed at 5 volt, but some will not rotate at all if the voltage is under 7 volt and etc.

Other example scenario :

The owner is using pwm controller capable of delivering 0-100% signal, and with

only single pot from this controller, he is able to control his mixed pwm fan and number of classic fans through this converters, and he is expecting ..

At 0%, it will be driving the fan at 5 volt, cause he doesn't want his fans to stop rotating at all, and while at 100% will be equal to 12 volt for max speed. Probably this is for his rad's fans.

And he has other identical converter and wants it to behave like this below for his case's fans ...

At 0%, this will be at 7 volt since that is the lowest voltage for case fans to spin up, and while at 100%, he wants that the output only maxed out at 10 volt since this is the max speed that his ears are allowed to tolerate.

Hope you see why direct translation from 0-100% to 0-12 volt is not a good idea, cause I'm worry it may not interest many people to participate in building it cause lack of flexibilities like I mentioned above.

Just my 2 cents.