- Joined

- May 24, 2002

- Location

- a place

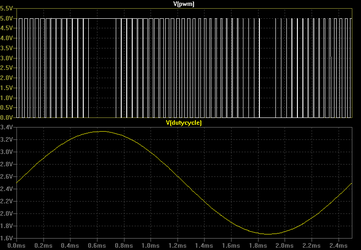

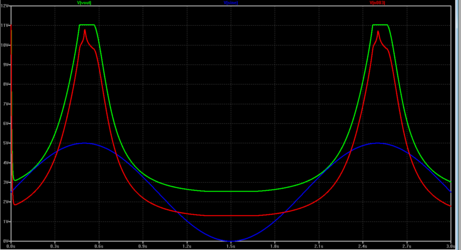

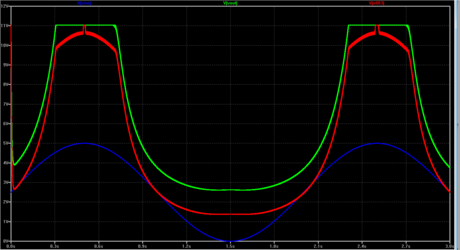

Didn't really help, it aligned the sine and the output but the problem is still there.

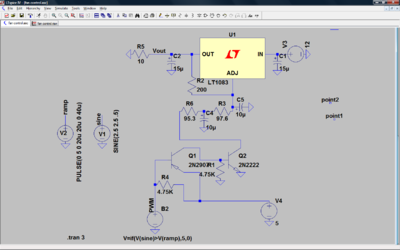

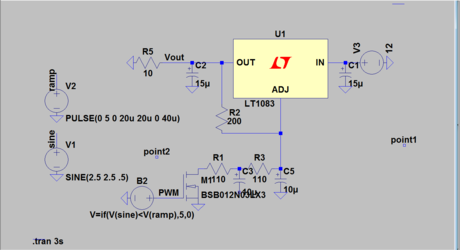

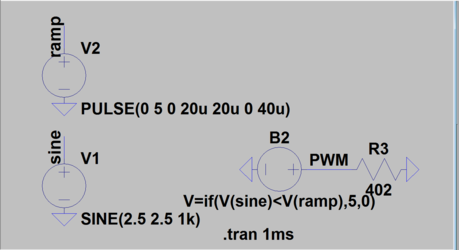

And I'll include the PWM setup as well.

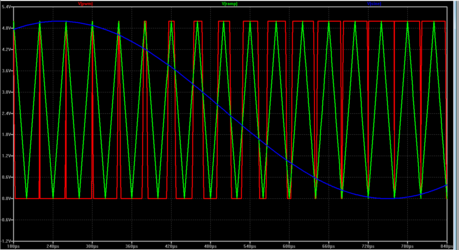

And there you can see that 0v sine PWM is at 100%.

Ideas anyone?

Oh, and this is where I found the PWM emulator

http://transistorgrab.de/en/2008/12/12/modulierte-pwm-mit-ltspice-darstellen/

And I'll include the PWM setup as well.

And there you can see that 0v sine PWM is at 100%.

Ideas anyone?

Oh, and this is where I found the PWM emulator

http://transistorgrab.de/en/2008/12/12/modulierte-pwm-mit-ltspice-darstellen/