My System:

CPU: Ryzen 7-3700X

GPU: 5700 XT (XFX Model No. RX-57XT8MFD6)

Motherboard: Asrock x570 Steel Legend

RAM: Corsair Vengeance Pro RGB – 16 Gb

Case: Cooler Master HAF Stacker 935

CPU Waterblock: EK Supremacy

GPU Waterblock: EK Vector Nickel-Plexi, 5700 XT with associated backplate

Radiators: 2 – XSPC EX240 2 X 120

I recently completed a long time project of mine to create a hardline custom water cooling with even a custom reservoir. It was my first time ever water cooling so I knew it was a lot to bite off but after tons of research and planning I finally built it. I’m still finishing up cosmetic items but it’s been running for the last few weeks (relatively) reliably. The CPU and GPU are in parallel loops right after their own radiator. My idle temperatures are about 40 C for the CPU and GPU. Under load such as gaming I will get up to about 50C-CPU and 58C-GPU. That seems fine to me but my biggest concern is the GPU junction temperature. Under load like with Firestrike it immediately spikes to 90, in about 10 minutes in it gets to 100C. Originally I was seeing 110C even faster than that. I think the high temps may have crashed the card a few times while playing Borderlands 3 but that game has its own bugs so I'm not completely sure.

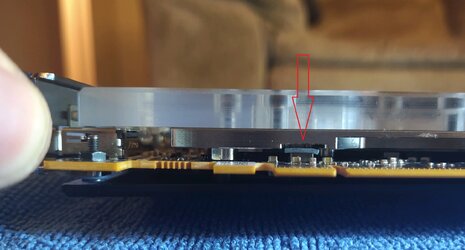

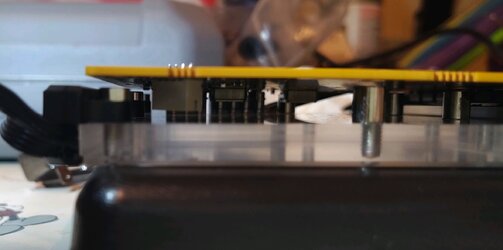

Since noticing this, I have been working with EK but their response is about one time a day so I am looking for some more timely help here. I have removed the block, cleaned and reapplied the thermal paste, pea method on the second try as opposed to the X that EK’s manual calls for. Thermal pads seemed to be sitting nicely as well. What I think is causing my issue is that the water block doesn’t fit flush with the card, causing it to curve when I torque all the screws down. One standoff on the I/O port side would not sit correctly and I practically had to strip the screw to bring it in. I didn’t want to do it but EK said it needed to be flush. I have confirmed through XFX that this is definitely an AMD reference card and they made no modifications to the board.

Is there anyone else out there water cooling a 5700 XT? Have they dealt with similar junction temperatures that they can’t bring down? Any other suggestions on how to fix this? I know both Alphacool and Corsair have similar blocks for the 5700 XT but I would love to avoid that headache if I can.

CPU: Ryzen 7-3700X

GPU: 5700 XT (XFX Model No. RX-57XT8MFD6)

Motherboard: Asrock x570 Steel Legend

RAM: Corsair Vengeance Pro RGB – 16 Gb

Case: Cooler Master HAF Stacker 935

CPU Waterblock: EK Supremacy

GPU Waterblock: EK Vector Nickel-Plexi, 5700 XT with associated backplate

Radiators: 2 – XSPC EX240 2 X 120

I recently completed a long time project of mine to create a hardline custom water cooling with even a custom reservoir. It was my first time ever water cooling so I knew it was a lot to bite off but after tons of research and planning I finally built it. I’m still finishing up cosmetic items but it’s been running for the last few weeks (relatively) reliably. The CPU and GPU are in parallel loops right after their own radiator. My idle temperatures are about 40 C for the CPU and GPU. Under load such as gaming I will get up to about 50C-CPU and 58C-GPU. That seems fine to me but my biggest concern is the GPU junction temperature. Under load like with Firestrike it immediately spikes to 90, in about 10 minutes in it gets to 100C. Originally I was seeing 110C even faster than that. I think the high temps may have crashed the card a few times while playing Borderlands 3 but that game has its own bugs so I'm not completely sure.

Since noticing this, I have been working with EK but their response is about one time a day so I am looking for some more timely help here. I have removed the block, cleaned and reapplied the thermal paste, pea method on the second try as opposed to the X that EK’s manual calls for. Thermal pads seemed to be sitting nicely as well. What I think is causing my issue is that the water block doesn’t fit flush with the card, causing it to curve when I torque all the screws down. One standoff on the I/O port side would not sit correctly and I practically had to strip the screw to bring it in. I didn’t want to do it but EK said it needed to be flush. I have confirmed through XFX that this is definitely an AMD reference card and they made no modifications to the board.

Is there anyone else out there water cooling a 5700 XT? Have they dealt with similar junction temperatures that they can’t bring down? Any other suggestions on how to fix this? I know both Alphacool and Corsair have similar blocks for the 5700 XT but I would love to avoid that headache if I can.