Woahhh... lots of update around here !!! Sorry guys, been so busy lately that I missed all the fun stuff here.

The result? Squealing and pulsating whine at low RPM, and of course no tachometer. There are of course ways to reduce the extraneous noise, but no way to recover tachometer functionality or to reduce the need for heatsinks on the FET and Schottky diode with high current loads.

This more "primitive" method of PWM will never be as good as the controller in this thread... it doesn't even come close, although it controls low powered fans very nicely indeed - the pot is extremely sensitive and linear speed adjustment is very precise.

I tried to explain to the dude (who, for the record, is a really nice guy) the ENORMOUS difference between a standard fan motor and a designated PWM fan motor. I happened to mention the "ticking" drawback of a modulated supply voltage, and he asked why it would tick worse when it's slower, and I had to do my research. After looking around for a while I found

this PDF document which is a very, very nice in-depth explanation of what happens to fan motors when the supply voltage is modulated.

Apparently there are techniques to suppress the extraneous noise resulting from the low duty cycle, which involves "smoothing the PWM impulse torque profile with the addition of a base capacitor," but even the author of this article throws in the towel where high current fans are concerned, saying DC speed control is probably a better option. (I'm pretty sure the article was written before PWM fans came on the scene!)

Dave, thanks a lot

, that is really an excellent example on how bad it is to pwm the fan directly at the power line. Regarding the app note on smoothing the pwm power using cap, you can see that even at low power fan, the smoothed current is not that smooth, still it has those ripples shown by the bulging wave. The higher the current, you need a really huge capacitor to smooth it out that at certain level, its not practical anymore. Also its a very crude method and will never get a perfect smooth straight line if just using a cap, unless using a gigantic cap that can totally flat it out, but the fan will react slowly on the speed adjustment since the gigantic cap is dragging the controller output.

Anyway, this is a really good reference, should someday anyone here encountered such situation like Dave, just point to this video, it will save your sanity trying to explain and argue about it.

Again, thank you Sir !

Thanks for sharing LennyRhys! Nevertheless, to the controller in this thread it it essentially that the fan has a fourth wire. Perhaps the guy you've battled with

does not know the advantages of a real pwm-support by the fans internal circuit board. I'm afrait the most fans on the marked, even the most sought after are non-pwm-fans as the noctua's and silent wings etc.

Comparing the usual fan-controllers by continous voltage control with this thread controllers, the others are really ridiculous. I love to pwm fans

Nortor, looks like you're having lots of fun lately, isn't it ?

Glad to hear that.

Yeah, most people once they tasted the sweetness of pwm fan

, they will never look back, like my self, I will never buy non pwm fan anymore unless they're really-really good fan or its really dirt cheap.

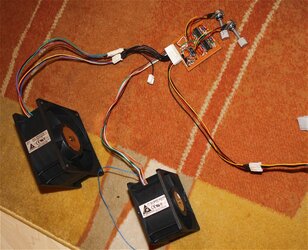

That double gfb0912shg fans are really monster, can't wait to see the video.

Btw, as Bob pointed out, floppy disk power connector probably is not that good for high current, its rated "theoritically" at 3 to 4 amp, and reality it will much less.

Suggesting to connect the pos and neg cables from those monster directly from the molex connector, or change the pwm connector into something bigger and beefier.

Weak connector will supplies less power to those monster fan and there is a possibility that it will overheated as well, just becareful when playing high current/power toys.

I don't understand, why people keep PWM-ing their linear fan

do they even realize that they actually applying fast on/off on their power line of the fan?

Its about awareness inVain, most people especially from the olde days of using 2 or 3 wires fan, those are the only methods to slow down a powerfull fan, cause using linear is really not efficient, and looks like they never catch up with this newer 4 wires pwm generation and thought its the same thing.

Hopefully this thread is contributing even a tiny bit in bringing this awareness to the mass.

Btw, love that industrial black box you built there, really awesome job you've done there, looks so professionally built.

Suddenly realized that A) I hadn't posted a video with my new (to me, old and replace to washington state U) ozyscope, nor had I aimed it at my attiny85 based fan controller!

Sidenote: I intend to find myself a decently juicy PNP mosfet and see if I can make a PWM linear fan controller work like a buck circuit.

We'll see.

Cool video Ed, glad to see you're having fun with your nice new toys there.

Also if you can hook the 2nd channel at the fan's rpm wire with a pull up resistor and see the nice rpm pulse that will vary according to the fan's speed.

**WARNING: BRIEF TANGENT AHEAD**

**WARNING: BRIEF TANGENT AHEAD**

does not know the advantages of a real pwm-support by the fans internal circuit board. I'm afrait the most fans on the marked, even the most sought after are non-pwm-fans as the noctua's and silent wings etc.

does not know the advantages of a real pwm-support by the fans internal circuit board. I'm afrait the most fans on the marked, even the most sought after are non-pwm-fans as the noctua's and silent wings etc.

, that is really an excellent example on how bad it is to pwm the fan directly at the power line. Regarding the app note on smoothing the pwm power using cap, you can see that even at low power fan, the smoothed current is not that smooth, still it has those ripples shown by the bulging wave. The higher the current, you need a really huge capacitor to smooth it out that at certain level, its not practical anymore. Also its a very crude method and will never get a perfect smooth straight line if just using a cap, unless using a gigantic cap that can totally flat it out, but the fan will react slowly on the speed adjustment since the gigantic cap is dragging the controller output.

, that is really an excellent example on how bad it is to pwm the fan directly at the power line. Regarding the app note on smoothing the pwm power using cap, you can see that even at low power fan, the smoothed current is not that smooth, still it has those ripples shown by the bulging wave. The higher the current, you need a really huge capacitor to smooth it out that at certain level, its not practical anymore. Also its a very crude method and will never get a perfect smooth straight line if just using a cap, unless using a gigantic cap that can totally flat it out, but the fan will react slowly on the speed adjustment since the gigantic cap is dragging the controller output.