- Joined

- Dec 19, 2012

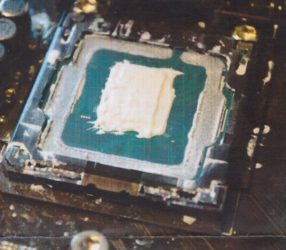

I'm posting this here and anyone can chime in with their experiences/techniques. I have never had good luck with Intel delids and LN2 I always seem to end up popping the TIM. I came across this post at ROG forums and looks like I might be doing it wrong. I never have tried using this much paste. If anyone has some tips on keeping a good contact I'm all ears. Pretty sure that's a pic of Dre8auer

With initial data obtained, CPUs are de-lidded to replace the stock thermal interface material (TIM). TIM choice is critical because the compound needs to be malleable enough to cope with the contraction and expansion of surfaces during extreme benchmarking. Eventual fractures are inevitable, but some materials perform better than others in this regard. Application methods are also a far cry from the conservative, rice-grain-sized amount required for conventional setups. A liberal quantity of paste is spread over the die and surrounding PCB to reduce the chances of dreaded ‘paste crack’ and to help improve thermal transfer.