- Joined

- Dec 16, 2015

started a new build today over the past few months i have slowly been snagging deals to build a micro atx media/gaming/what ever rig

got a pretty sweet deal on what seems a decent cooler. the gammax400 comes with a single fan and extra mounting clips for an additional fan for push pull.

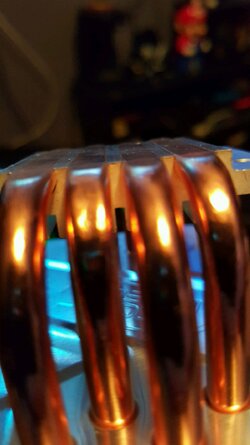

since i am only using an 95w athlon i figured a single fan should be plenty (pc specs below) apon further inspection of the cooler i could not help but notice

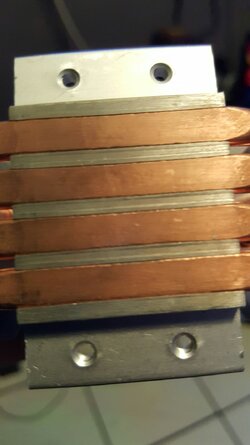

the absolute **** quality of the base plate that comes incontact with the cpu heat spreader. the copper heat pipes are worked into the base and the surface of

the plate with the pipes is very un-even, rough, and not aligned properly. but as that may be i figured no company would be that blind and produce or let somthing

go into production like that so i gave it ago i used artic silver thermal paste as i do on all my builds. fired up the comp into bios and what a shocker cpu is at 61c !!

made me laugh at first as i shut it down. i took the cooler off to inspect the paste and see how it spread and the paste was having trouble spreading past the gaps

between the pipes and aluminum base. i dont know if this is a common problem with deepcool products. but for the meantime i threw the **** stocker heatsink that

Amd provides(even used the pre applied thermal paste) fired the comp back into bios and the cpu is siting at a cool 31c. which once again gave me a good laugh

pc specs!!!

amd athlon 95w 860k

asus fm2 motherboard

thermaltake v21 case

asus r7 370 strix

evga 500w psu

got a pretty sweet deal on what seems a decent cooler. the gammax400 comes with a single fan and extra mounting clips for an additional fan for push pull.

since i am only using an 95w athlon i figured a single fan should be plenty (pc specs below) apon further inspection of the cooler i could not help but notice

the absolute **** quality of the base plate that comes incontact with the cpu heat spreader. the copper heat pipes are worked into the base and the surface of

the plate with the pipes is very un-even, rough, and not aligned properly. but as that may be i figured no company would be that blind and produce or let somthing

go into production like that so i gave it ago i used artic silver thermal paste as i do on all my builds. fired up the comp into bios and what a shocker cpu is at 61c !!

made me laugh at first as i shut it down. i took the cooler off to inspect the paste and see how it spread and the paste was having trouble spreading past the gaps

between the pipes and aluminum base. i dont know if this is a common problem with deepcool products. but for the meantime i threw the **** stocker heatsink that

Amd provides(even used the pre applied thermal paste) fired the comp back into bios and the cpu is siting at a cool 31c. which once again gave me a good laugh

pc specs!!!

amd athlon 95w 860k

asus fm2 motherboard

thermaltake v21 case

asus r7 370 strix

evga 500w psu