- Joined

- Mar 18, 2015

Depends on the solder but solder is generally a bit better than the average TIM. Electronics solder will contain silver/silver alloys to aid in conduction but your basic plumbing lead solder is still okay for this purpose I think. I wouldnt make up a circuit board with it or anything, but filling in a couple gaps shouldn't have a huge detriment.

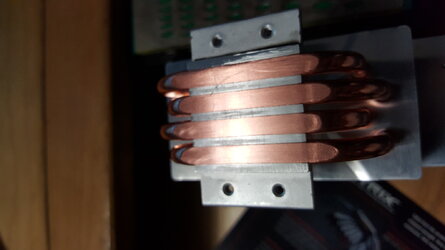

While it looks to me like the heat pipes are flush with the rest of the plate I definitely see some gaps around the pipes. I wonder if maybe the aluminum isnt attached to the copper poorly or there is air trapped between the aluminum and the copper (inside the plate). With as poorly as that thing is cooling there might even already be a hole in one of the heat pipes. I would try sending it back to the manufacturer before modding it. If you get another that works the same way then go for it

While it looks to me like the heat pipes are flush with the rest of the plate I definitely see some gaps around the pipes. I wonder if maybe the aluminum isnt attached to the copper poorly or there is air trapped between the aluminum and the copper (inside the plate). With as poorly as that thing is cooling there might even already be a hole in one of the heat pipes. I would try sending it back to the manufacturer before modding it. If you get another that works the same way then go for it