I recently bought the EK-XTOP D5 and I also bought the EK-Quantum Kinetic FLT Pump/Reservoir Body (120mm). This reservoir is listed as being compatible with both the DDC and D5 pumps. I was concerned about how this was accomplished since the two pumps have a different impeller and volute shape.

I was really surprised by how different the volute shape is between the XTOP and FLT. At least in the case of the D5 pump (I don't have a DDC). The volute on the FLT is tiny compared to the XTOP. I decided to do a simple flow test between the XTOP and FLT to see if there was an impact on performance.

I measured a 25-30% reduction in the flow rate between the two tops. The XTOP had a flow rate of 3.9 gpm (14.9 lpm) and the FLT had a flow rate between 2.7 gpm (10.4 lpm) and 3.0 gpm (11.4 lpm) depending on which ports were used. I was pretty disappointed.

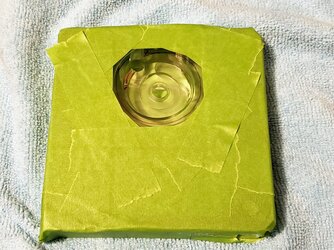

I looked at the FLT top and thought I might be able to carve out the shape of the XTOP volute into the FLT acrylic. So that's what I did. I used the XTOP to trace out a stencil and transferred the profile onto the FLT.

A generous application of tape to protect the acrylic surfaces.

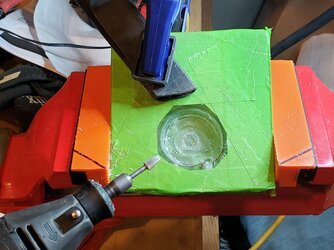

I used a Dremmel 117 bit to do the carving.

The true profile would have brought the discharge into the gasket groove. To avoid that I undercut the acrylic near the discharge. I also ported out the actual discharge to open it up and smooth it out.

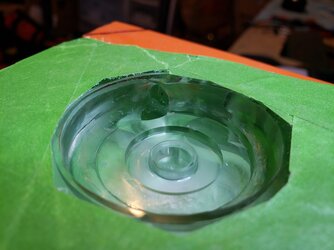

It's far from perfect, but I'm happy with how it turned out.

I removed quite a bit of material. It's hard to see the profile in the after picture so I added an outline.

So what was the result? I reran my flow test and I measured 3.5 gpm (13.1 lpm) or a 12% flow reduction from the XTOP. I think the improvement over the stock FLT is pretty good.

Thoughts:

I'm not sure why there isn't a better volute profile from the factory. They already have the tooling to carve out an XTOP. I suspect the reservoir is optimized for the DDC pump, but I don't have a DDC pump to test.

Pumps want a straight unrestricted path to the inlet (Like the XTOP). There's a sharp 90 degree turn to the inlet in the FLT. The large open area around the FLT inlet may also cause some vortexing that impedes inlet flow. I suspect adding flow straighteners at the inlet would further improve performance.

Did I perfectly match the XTOP volute profile? Probably not. Other than the outline it was done by eye. Maybe it could be better.

This wasn't too hard. If you're handy I would recommend making this modification to your FLT reservoir.

I was really surprised by how different the volute shape is between the XTOP and FLT. At least in the case of the D5 pump (I don't have a DDC). The volute on the FLT is tiny compared to the XTOP. I decided to do a simple flow test between the XTOP and FLT to see if there was an impact on performance.

I measured a 25-30% reduction in the flow rate between the two tops. The XTOP had a flow rate of 3.9 gpm (14.9 lpm) and the FLT had a flow rate between 2.7 gpm (10.4 lpm) and 3.0 gpm (11.4 lpm) depending on which ports were used. I was pretty disappointed.

I looked at the FLT top and thought I might be able to carve out the shape of the XTOP volute into the FLT acrylic. So that's what I did. I used the XTOP to trace out a stencil and transferred the profile onto the FLT.

A generous application of tape to protect the acrylic surfaces.

I used a Dremmel 117 bit to do the carving.

The true profile would have brought the discharge into the gasket groove. To avoid that I undercut the acrylic near the discharge. I also ported out the actual discharge to open it up and smooth it out.

It's far from perfect, but I'm happy with how it turned out.

I removed quite a bit of material. It's hard to see the profile in the after picture so I added an outline.

So what was the result? I reran my flow test and I measured 3.5 gpm (13.1 lpm) or a 12% flow reduction from the XTOP. I think the improvement over the stock FLT is pretty good.

Thoughts:

I'm not sure why there isn't a better volute profile from the factory. They already have the tooling to carve out an XTOP. I suspect the reservoir is optimized for the DDC pump, but I don't have a DDC pump to test.

Pumps want a straight unrestricted path to the inlet (Like the XTOP). There's a sharp 90 degree turn to the inlet in the FLT. The large open area around the FLT inlet may also cause some vortexing that impedes inlet flow. I suspect adding flow straighteners at the inlet would further improve performance.

Did I perfectly match the XTOP volute profile? Probably not. Other than the outline it was done by eye. Maybe it could be better.

This wasn't too hard. If you're handy I would recommend making this modification to your FLT reservoir.