ok, finally got the shopping done. RL sure interferes with this folding and hvac stuff!

3/4" copper aint cheap but not much more than 1/2".

Will tally the costs up later, right now the CC is keeping track of it

If i get ambitious when I expand it i will try some other cheaper materials.

As to scap sources, for now i am trading the $ for my time. I have a boat in the driveway to get some rigging done to and a ton of yardwork. Just to mention a few things on my non-folding to do list.

Fishy, ya i know i dont really need a res but i figured i would be filling and draining this a few times before i am done so it should make things easier. Having had the joy of priming water lines every spring at the cottage with long lines it should go easier. 5' in my current wc rig does not seem the same as filling 50' of line. Will certainly be easier than the cottage with nearly 200' of 1 1/4" pickup line to prime over uneven ground.

/edit And thinking about this, it is some overkill since the cottage stuff is presurized to 40 lbs. There really is not mich priming here with the pump adjacent to the water supply. But it will be a lot easier to pour a lot of water into a res than a t line.

Picked up a few ball type 1/2" valves for the lines on the rig. They take a bit of force to turn on/off but they will not create any flow restriction when open.

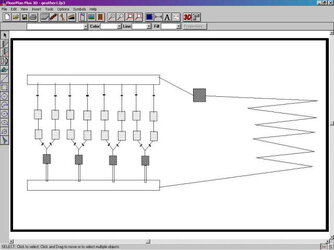

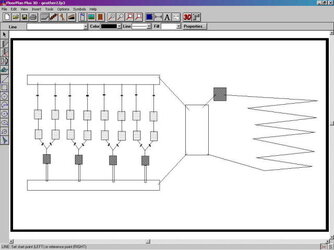

Nice diagrams guys ... now all i need is a supervisor for my construction steps.

We'll see if i get ambitious to do some digging tonight. Pity my neighbours aren't closer ... would surely get some curious stares digging at night

Time to assemble the res and solder the copper.

)

)