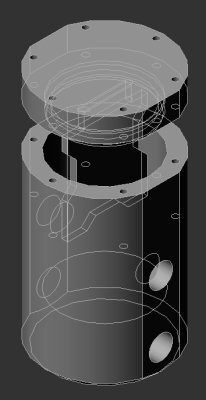

I remember Diggrr had a pretty neat yet simple concept for a vortex style one .

"For tools, I used my dremel with a carbide cutter (looks like a flat tipped drill) to make the holes, then the bottom one was tapped with a 1/2" NPT tap for the fitting. The inlet was a pain to dremel in there, then I marine gooped the copper tube into place.

The rest was just patience and a small hacksaw and drill.

The center divider was made to press fit into place at first, so I could test it, pop it out using a hooked wire from the top, resize the hole, and reinsert to test again. I glued it when I was happy.

Bevel the sharp edges so that it doesn't scratch the inside of tube when removing it.

The larger the hole, the less downward velocity, the shorter the vortex, the less chance of air getting sucked down. In the pic, there's an air bubble hovering over the hole, but when it get's big enough, it just goes back up into the vortex.

You can color clear plastic with those "anodizing" paints called metalcast by duplicolor (pepboys, auto zone). But beware that scratching is pretty easy, and the color would come off.

I think tap MIGHT have colored plastics...don't know.

Maybe testor's model paints would work better, they have clear colors, and their paints rock.

For good visibility through the tube though, I just used a single 6" blue neon tube behind it that really looked cool.

I'd gotten the idea from a museum exhibit i'd found online. They had one that was 8' tall and about 2.5' across. I invented the divider plate to keep the tube sitting flat in the case without a fitting on the bottom (also made for a taller vortex that still fit in the case). The cube's aren't all that tall, like mid tower cases." - diggrr

I believe he still posts and is an active member , probably one of the most interesting ideas I had seen and was very helpful when I was "trying" to make mine .