- Joined

- May 12, 2015

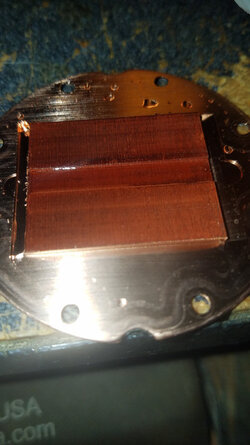

The waterblock base on my riing 360 from TT has turned into a galiumcopper alloy thanks to liquid metal bonding to the copper.. Leaving a silver.gray almost stain that wont come off.. Liquid metal sucks.. it did the same thing to my 4790kIHS inside and outside and to the core die.. And i had it on for less than a week

Never using that stuff again.. After some reading galium aparently bonds to copper to create a new alloy.. Of which im not sure has worse or better or the same thermal conductivity. So i want it off.

The waterblock also isnt polished or smoothed out very well.. It has rings starting direct center expanding outward that looks identical to what a tree looks like when you cut it down. Each ring has grooves i ca feel with my finger specially my nails..

So i figured lapping this block would yeild two advantages.. One to get the new alloy off and back to copper.. And two to smooth the rings down and maybe help with temps.

What do you guys think ?

Never using that stuff again.. After some reading galium aparently bonds to copper to create a new alloy.. Of which im not sure has worse or better or the same thermal conductivity. So i want it off.

The waterblock also isnt polished or smoothed out very well.. It has rings starting direct center expanding outward that looks identical to what a tree looks like when you cut it down. Each ring has grooves i ca feel with my finger specially my nails..

So i figured lapping this block would yeild two advantages.. One to get the new alloy off and back to copper.. And two to smooth the rings down and maybe help with temps.

What do you guys think ?