Hi,

So my mobo is Asus M4A77T and I've decided to do heatsinks to its vrm's. I'm going to use Athlon 64 x2 stock cooler for this and cut pieces from it. I'm just not 100% sure that which all components I should cover with the heatsink and what kind of thermal paste I should use to stick them into it.

I can't find that damn thermal paste glue from anywhere in here finland... Oh, there is one store which sells it 18€ but you have to wait for it 2-3 weeks. Just so stupid. So is there anything else I could use, how about those thermal pads, do they hold them in place?

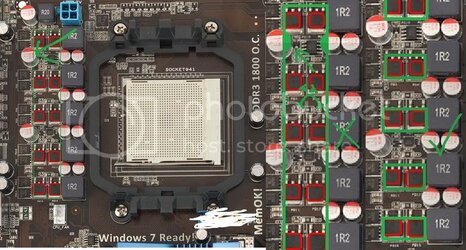

And here's a picture where I think the heatsinks would come on. So is it like this...?

So my mobo is Asus M4A77T and I've decided to do heatsinks to its vrm's. I'm going to use Athlon 64 x2 stock cooler for this and cut pieces from it. I'm just not 100% sure that which all components I should cover with the heatsink and what kind of thermal paste I should use to stick them into it.

I can't find that damn thermal paste glue from anywhere in here finland... Oh, there is one store which sells it 18€ but you have to wait for it 2-3 weeks. Just so stupid. So is there anything else I could use, how about those thermal pads, do they hold them in place?

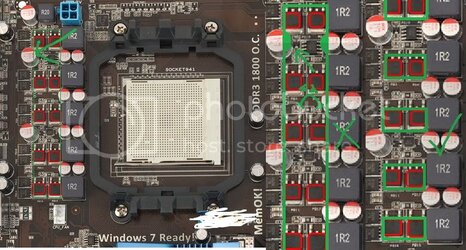

And here's a picture where I think the heatsinks would come on. So is it like this...?

Best option really.

Best option really.