So I'm new to water cooling but I've watched a TON of content from big names like JayzTwoCents on water cooling configurations.

I'm running a Ryzen 7 1800x and Asus DUAL RTX 2080 Ti. CPU is not overclocked, GPU power slider has been moved from 100% to 120% but the temperature numbers seem to be the same between both.

My loop:

Pump/Res Combo > GPU > CPU > Radiator > Radiator > Repeat

The Pump is a D5 with 300ml reservoir.

EKWB Water block for GPU

EKWB Water block for CPU

Radiators are Cool Stream XE 480mm x 60mm x2

8 Vardar 120mm SP fans in push configuration

Might be overkill but it was built to be.

So here is the question...

When I'm running an intensive game like Digital Combat Simulator with VR and an auxiliary air conditioner running in my room cooling room temps to around 18.8c I'm seeing some pretty hot temps from the GPU while the CPU is chugging along just fine at normal temperatures. At idle the GPU is running about 6-10ish Celsius above room temperature. When the load is removed from the GPU it cools very quickly which makes me wonder if that's normal behavior or an indicator the water block might actually be seated properly and doing its job.

When running in DCS I'm seeing the GPU temps fluctuate quickly between 67 to 84c with the average while flying being above 84c. When running a non intensive game like RL my CPU temps drop even more and the GPU bounces around between 67c and 84c with the average being in the high 60s. Again the CPU temps are normal and the temps are stable on the GPU. The ASUS Dual has some negative reviews regarding how hot it runs on the air cooler and I'm wondering if the temps I'm seeing on water are just as good as it gets with these toasty 2080 Ti's or if I might have a thermal paste/seating issue with the water block. I used an adequate amount of meh grade Coolermaster thermal paste. Thermal pads were all installed per manufacture instructions and all appear to be seating well when I pulled the water block off to check.

Loop has no kinks and has been purged of all visible air. No longer seeing the occasional bubble working it's way through the system anymore.

Just wanted to get the experts thought's on GPU performance specifically and not looking to get debates started over loop order or capacity unless someone honestly thinks that 2 480x60mm radiators aren't enough to cool this which I doubt would be the case. I'm ordering the Grizzly thermal paste and will try to re-seat the card once that comes in next week. As I type this my room temp is 22c GPU temp is hovering at 44c and CPU temp is down at 26c. Any information is greatly appreciated and thanks in advance!

-Josh

I'm running a Ryzen 7 1800x and Asus DUAL RTX 2080 Ti. CPU is not overclocked, GPU power slider has been moved from 100% to 120% but the temperature numbers seem to be the same between both.

My loop:

Pump/Res Combo > GPU > CPU > Radiator > Radiator > Repeat

The Pump is a D5 with 300ml reservoir.

EKWB Water block for GPU

EKWB Water block for CPU

Radiators are Cool Stream XE 480mm x 60mm x2

8 Vardar 120mm SP fans in push configuration

Might be overkill but it was built to be.

So here is the question...

When I'm running an intensive game like Digital Combat Simulator with VR and an auxiliary air conditioner running in my room cooling room temps to around 18.8c I'm seeing some pretty hot temps from the GPU while the CPU is chugging along just fine at normal temperatures. At idle the GPU is running about 6-10ish Celsius above room temperature. When the load is removed from the GPU it cools very quickly which makes me wonder if that's normal behavior or an indicator the water block might actually be seated properly and doing its job.

When running in DCS I'm seeing the GPU temps fluctuate quickly between 67 to 84c with the average while flying being above 84c. When running a non intensive game like RL my CPU temps drop even more and the GPU bounces around between 67c and 84c with the average being in the high 60s. Again the CPU temps are normal and the temps are stable on the GPU. The ASUS Dual has some negative reviews regarding how hot it runs on the air cooler and I'm wondering if the temps I'm seeing on water are just as good as it gets with these toasty 2080 Ti's or if I might have a thermal paste/seating issue with the water block. I used an adequate amount of meh grade Coolermaster thermal paste. Thermal pads were all installed per manufacture instructions and all appear to be seating well when I pulled the water block off to check.

Loop has no kinks and has been purged of all visible air. No longer seeing the occasional bubble working it's way through the system anymore.

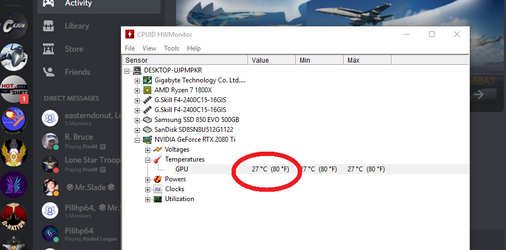

Just wanted to get the experts thought's on GPU performance specifically and not looking to get debates started over loop order or capacity unless someone honestly thinks that 2 480x60mm radiators aren't enough to cool this which I doubt would be the case. I'm ordering the Grizzly thermal paste and will try to re-seat the card once that comes in next week. As I type this my room temp is 22c GPU temp is hovering at 44c and CPU temp is down at 26c. Any information is greatly appreciated and thanks in advance!

-Josh

Last edited by a moderator: