- Thread Starter

- #21

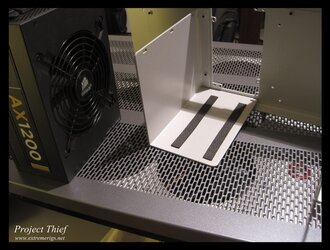

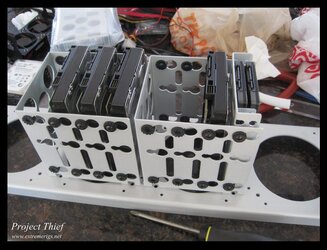

So while I was waiting for the screws, I decided to mount a reservoir to the motherboard tray. As the motherboard tray is HPTX there is a lot of spare space. Initially I wanted to also fit an RX360 on there, so that the motherboard/gpu/ram loop was self contained on the tray so that I could just pull it out and swap CPUs without disturbing that loop. Now I have another plan for the radiator instead. Here I am drilling the tray:

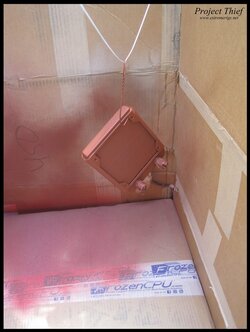

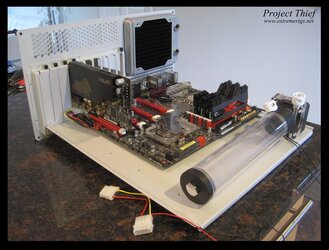

With the res mounted (it's a 250 EK multires if anyone cares and there's just enough room for a D5 underneath):

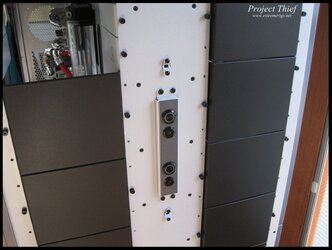

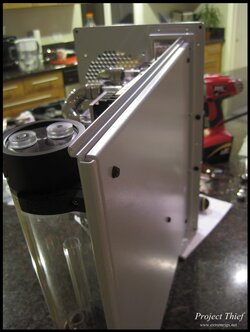

From the back with the reservoir mounted. You can see the two nuts holding it on:

Now with the motherboard tray back stiffening and tiding plate added:

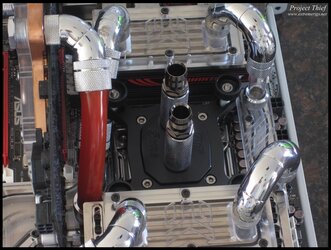

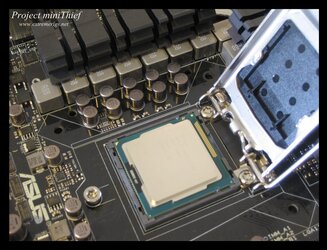

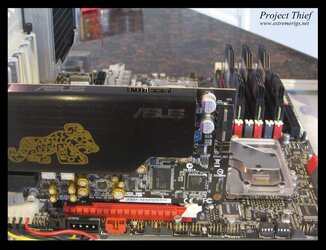

Here's another shot of the front also showing the new cpu block. BTW any barbs are just place holders.

A quick test inside the case:

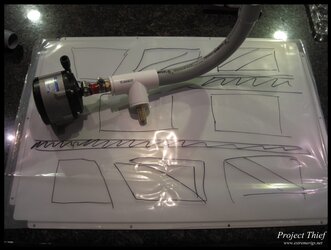

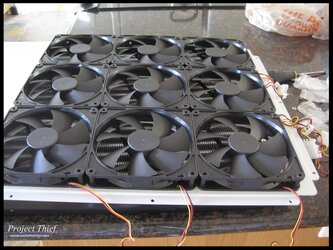

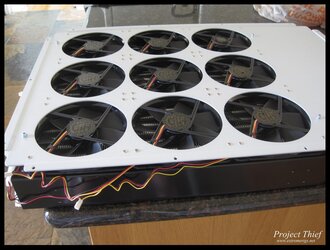

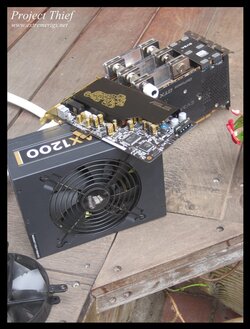

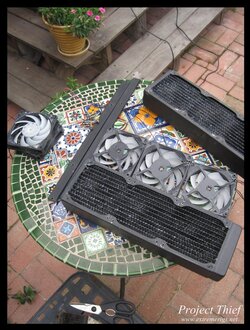

I also did a test run with the gtx560 radiator and the fan adapters with my new shiny 2150 rpm gentle typhoons!

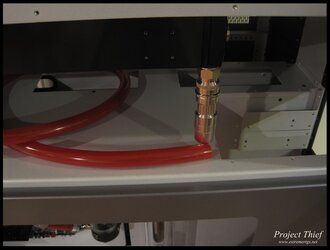

That was it for the night, then the next morning I found an extra fitting and connected the res to the ram block. Almost a straight line lol.

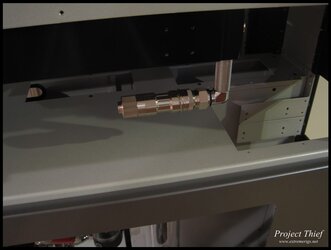

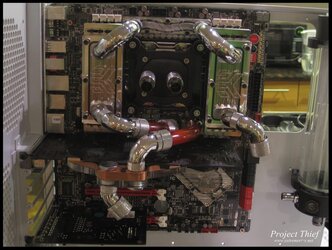

No one had photographed the new thumbscrews on the cpu block - so I took a couple of that also:

Again ignore the barbs, I haven't quite decided how to route the tube out of there yet.

With the res mounted (it's a 250 EK multires if anyone cares and there's just enough room for a D5 underneath):

From the back with the reservoir mounted. You can see the two nuts holding it on:

Now with the motherboard tray back stiffening and tiding plate added:

Here's another shot of the front also showing the new cpu block. BTW any barbs are just place holders.

A quick test inside the case:

I also did a test run with the gtx560 radiator and the fan adapters with my new shiny 2150 rpm gentle typhoons!

That was it for the night, then the next morning I found an extra fitting and connected the res to the ram block. Almost a straight line lol.

No one had photographed the new thumbscrews on the cpu block - so I took a couple of that also:

Again ignore the barbs, I haven't quite decided how to route the tube out of there yet.