Greetings all,

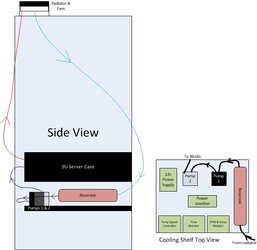

I'm in the process of constructing my first cooling loop. At the moment, I have the loop setup outside the case for testing, sans radiator. Currently, the testing setup is like this: reservoir -> pump 1 -> pump 2 -> water block 1 -> water block 2 -> water block 3 -> reservoir.

The components are:

My question centers on the pumps speed as measured by the reported RPMs and the longevity of the pumps. To reach the magic number of 1 GPM though the loop, the pumps are currently running @ 4440 RPM each.

So my questions are:

I'm in the process of constructing my first cooling loop. At the moment, I have the loop setup outside the case for testing, sans radiator. Currently, the testing setup is like this: reservoir -> pump 1 -> pump 2 -> water block 1 -> water block 2 -> water block 3 -> reservoir.

The components are:

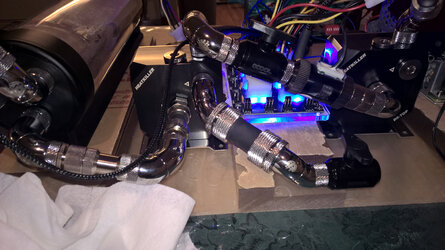

- Piping: All pipping and fittings are 3/8ID, 1/2OD

- Loop Turns: There no hard 90-degree turns

- Reservoir: Photon Res 270

- Pump 1 & 2: VPP655 Single Edition

- Pump Tops: Heatkiller D5-TOP

- WB 1: Heatkiller IV Pro

- WB 2: Heatkiller SB Rev3.0

- WB 3: Alphacool HF 14 Universal VGA Block - Copper Edition

- Radiator: Not present in testing loop

My question centers on the pumps speed as measured by the reported RPMs and the longevity of the pumps. To reach the magic number of 1 GPM though the loop, the pumps are currently running @ 4440 RPM each.

So my questions are:

- Is this a normal RPM range?

- Will running at this RPM setting continuously shorten the life expectancy of the pumps?

Last edited: