- Joined

- Sep 16, 2003

- Location

- Knoxville, TN

I was planning on doing a whole write up until I had an accident during reassembly that I assume had killed the card, fortunately it is very much alive! The most important thing is to use electrical tape around the die. If you don't have that you will kill the card. Why? Well the way the whole unit is designed it is broken up into 3 parts. You've got the shround up top, the flat sled which cools the VRMs and then finally the actual GPU heatsink itself. At least on mine the whole thing is sealed with epoxy so you don't have to worry about the interposer however the heatsink itself sits below the spine of the card that the sled uses to support it and it wants to shift around once you start to rotate the card right-side up. Unfortunately you cannot get to the heatsink without removing absolutely everything. The thermal pad is so large and is made of that chewing gum style stuff so it takes a fair amount of effort to dislodge.

So once everything is removed off the card including the rear I/O plate go ahead and clean and put down the electrical tape. Make sure it is sealed in front of the VRMs since you are likely going to slosh or spill something when you rotate the card like I did.

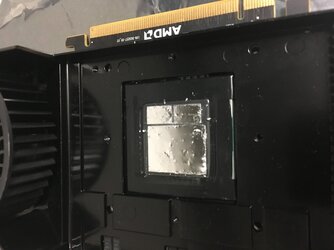

Once you've got the sled back on tight, die cleaned and LM applied this is where I screwed up. When you go to rotate the card make sure you have direct finger pressure on the heatsink block and the rear of the card. Once it is upside down make sure you place the center of the heatsink on top of a raised object like a coke can or a power supply or something raised enough to clear the spine of the sled. I did not do this and so when I lifted off to tighten the rear of the card since the bracket is so stiff the heatsink skittered off and I assumed the worst. FORTUNATELY! since I had Super33 tape down I could carefully clean the LM away and scoop it back onto the die for removal using a Q-tip. To scoop back onto the die I used a flathead screwdriver covered in a piece of electrical tape and that worked better than trying to scrub the excess off.

since I had Super33 tape down I could carefully clean the LM away and scoop it back onto the die for removal using a Q-tip. To scoop back onto the die I used a flathead screwdriver covered in a piece of electrical tape and that worked better than trying to scrub the excess off.

Once I fixed my screw up I placed the heatsink on top of a coffee mug I had lying around for added support to do the rear plate and everything else went just fine. I just want to spare someone a heart attack.

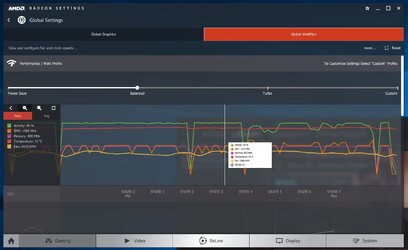

Before:

-20% Power / 960mhz memory

65C* @ 2384RPM

After:

-20% Power / 960mhz memory

65C* @ 1978RPM

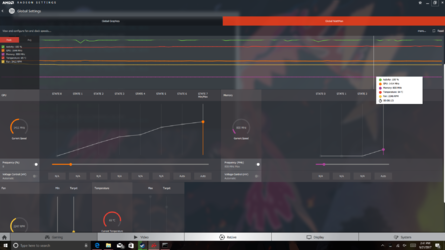

Seems to have helped quite a bit, temps now take a long while to reach peak as opposed to it being more or less instant. I can't say I recommend this for everyone until non-reference HSF designs arrive but for those with water blocks you can use liquid metal without issue on Vega. Lastly all the stock thermal pads appear to be .5mm for those interested. Photo below you can see the LM spray caused by the shifting heatsink. Also highest observed clocks so far were 1572 / 960 and that was with a targeted temp of 65C* at 3500RPM with 50% power offset.

So once everything is removed off the card including the rear I/O plate go ahead and clean and put down the electrical tape. Make sure it is sealed in front of the VRMs since you are likely going to slosh or spill something when you rotate the card like I did.

Once you've got the sled back on tight, die cleaned and LM applied this is where I screwed up. When you go to rotate the card make sure you have direct finger pressure on the heatsink block and the rear of the card. Once it is upside down make sure you place the center of the heatsink on top of a raised object like a coke can or a power supply or something raised enough to clear the spine of the sled. I did not do this and so when I lifted off to tighten the rear of the card since the bracket is so stiff the heatsink skittered off and I assumed the worst. FORTUNATELY!

since I had Super33 tape down I could carefully clean the LM away and scoop it back onto the die for removal using a Q-tip. To scoop back onto the die I used a flathead screwdriver covered in a piece of electrical tape and that worked better than trying to scrub the excess off.

since I had Super33 tape down I could carefully clean the LM away and scoop it back onto the die for removal using a Q-tip. To scoop back onto the die I used a flathead screwdriver covered in a piece of electrical tape and that worked better than trying to scrub the excess off. Once I fixed my screw up I placed the heatsink on top of a coffee mug I had lying around for added support to do the rear plate and everything else went just fine. I just want to spare someone a heart attack.

Before:

-20% Power / 960mhz memory

65C* @ 2384RPM

After:

-20% Power / 960mhz memory

65C* @ 1978RPM

Seems to have helped quite a bit, temps now take a long while to reach peak as opposed to it being more or less instant. I can't say I recommend this for everyone until non-reference HSF designs arrive but for those with water blocks you can use liquid metal without issue on Vega. Lastly all the stock thermal pads appear to be .5mm for those interested. Photo below you can see the LM spray caused by the shifting heatsink. Also highest observed clocks so far were 1572 / 960 and that was with a targeted temp of 65C* at 3500RPM with 50% power offset.

Last edited: