I recently read an older article about using a refrigerator to cool the coolant running through a overclocking build back in 2002. I have been considering doing something similar: Using a mini freezer to cool ethylene glycol. I was wondering if people would be willing to take a look and offer some advice on question I had.

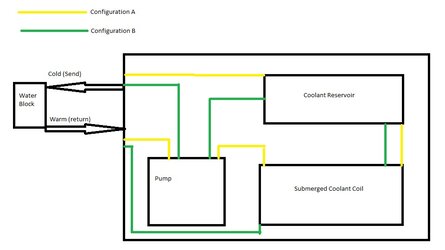

The system works by pumping the coolant through the usual water block formation from a reservoir in the freezer. The coolant is returned, and instead of being run through a standard cooling coil its is run through a submerged coil for more rapid transference before being returned to the reservoir. My major questions are twofold. The first question I have is what size pump do you think I should look at for a system like this (~1-3 liters). The second is do you think the pump is best placed in configuration A) where it pulls the warm coolant from the water block and pushes it through the cooling coil, or in configuration B) where it pulls from the reservoir and pushes cold coolant into the water block. I'm not sure in a system this small it is entirely relevant, but I'd appreciate your input. I plan on using 1/4 tubing for the majority of the project. I may also expand he system to cover my GPU's, but I'm not sold on that yet.

The system works by pumping the coolant through the usual water block formation from a reservoir in the freezer. The coolant is returned, and instead of being run through a standard cooling coil its is run through a submerged coil for more rapid transference before being returned to the reservoir. My major questions are twofold. The first question I have is what size pump do you think I should look at for a system like this (~1-3 liters). The second is do you think the pump is best placed in configuration A) where it pulls the warm coolant from the water block and pushes it through the cooling coil, or in configuration B) where it pulls from the reservoir and pushes cold coolant into the water block. I'm not sure in a system this small it is entirely relevant, but I'd appreciate your input. I plan on using 1/4 tubing for the majority of the project. I may also expand he system to cover my GPU's, but I'm not sold on that yet.