- Joined

- Mar 19, 2013

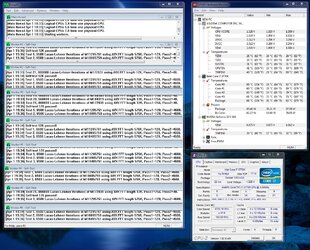

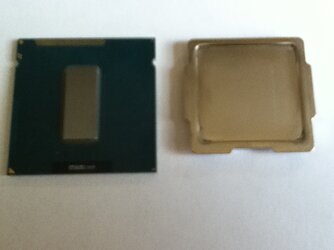

I delidded my 3770k this morning with a stanley razer and polished it with a soft tipped dremmel bit. I decided that using a hammer was probably not my best choice of tools.

Under load temps

core before after

0 82 50

1 80 56

2 79 58

3 75 58

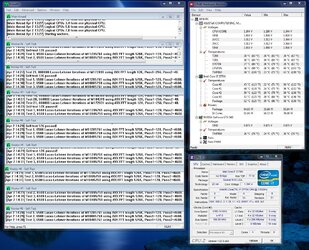

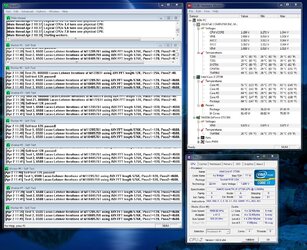

I also removed the lid and retaining bracket and mounted (gently) the Koolance waterblock directly on the die.

I'll show the proof when I figure out how to upload jpegs (seems to want a url)

Under load temps

core before after

0 82 50

1 80 56

2 79 58

3 75 58

I also removed the lid and retaining bracket and mounted (gently) the Koolance waterblock directly on the die.

I'll show the proof when I figure out how to upload jpegs (seems to want a url)