Hi everybody! This is my first post here in about 3.5 years so I might as well be a new member. Please don't get scared off by the big post, there's a lot of important info and it really is an interesting problem for those that like WC system design.

I'm in need of some water cooling advice in preparation for my new computer. Of course if this was normal system I wouldn't bother you all like this, but this one is a little different. I'm about halfway done with the case, it's a complete from-scratch build with stainless steel tubing, but the special thing about it is that the frame is part of the water cooling system (the second one I've done this way, here's the first:

http://i5.photobucket.com/albums/y156/zackbass/IMG_0023compressedSmall.jpg ) and it's being built like a safe. That means innocent things like unguarded airholes are a no-no. I've got a detailed worklog over at bit-tech:http://forums.bit-tech.net/showthread.php?t=89645 that I'd suggest skimming to get a feel for the design but I'll lay out a summary here.

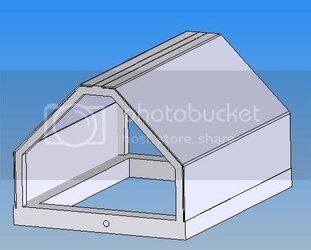

Here's a render that shows off the basic structure:

Its footprint is about 19.5"x14.5". The large bottom section and the two uprights are connected internally and form the reservoir while the connecting section up top is internally separated and is the distribution manifold. The two side doors lift up on hinges at the top. A transmission cooler will be mounted on small standoffs to the slanted section of the outside of each door.

The system is going to be entirely fanless, and to add to that it's being built like a safe so internal airflow is going to be almost nonexistant. I won't be overclocking, but the load on the system is going to be pretty substantial.

Here's a partial list of major heat contributing hardware inside the case:

Dual Core Pentium 4

Undetermined mobo

Antec Neopower

Two 7200RPM HDDs

High end video card

Eheim 1048 (I hope it's beefy enough)

Now, I wouldn't try something like this if I didn't know what I was doing, so there's no need telling me that it's too hard or that it'll never work, so let's get down to business and make it work.

My two transmission coolers just came in today. They are Fluidyne units, but they're unlike anything I've ever seen before. Here are some pics:

In the center of the bottom picture you can see the internal structure of the tubes. It's a very interesting design, my gut feeling is that they're extemely effective but pretty restrictive (confirmed by the "put my mouth over the inlet and blow" test). I have yet to decide whether to run them in series or parallel. Some air holes will be drilled through the doors directly underneath the rads to get some air circulation (the rads guard againt a breach through the holes). I've yet to find a place where I can put the inlet holes and not compromise security. I may just have to pick a spot out in the open and use some steel mesh to cover it.

The power supply modification is almost complete. I decided to go with a copper riser connected to a U-tube. It's all welded with near 100% penetration, so it's basically solid copper (no nasty solder interfaces to worry about). This is it in its most finished state:

So to recap we have the following to work with:

A custom case with a very large reservoir that slowly bleeds off heat

An Eheim 1048

A water cooled PSU

Two restrictive but highly effective rads

Nearly zero airflow

Keeping it in the spirit of a secure safe

What I need is suggestions on how to pull this off effectively and details on potential trouble spots. What components need to be water cooled since they don't have any airflow? Should I be worried about the northbridge or mobo power circuitry? How about the hard disks? I can whip up waterblocks for anything no problem, I have a Bridgeport milling machine in my shop and know how to use it.

I also need to pick waterblocks for the CPU and GPU. I'm not afraid to lay out some cash for the good stuff, I've come this far already. I would love to have someone's custom work but I'm not sure of what's out there and how to buy it.

Congratulations on making it to the end of my question(s), any and all help besides the assumed "you're crazy and it'll never work" is very much appreciated.

I'm in need of some water cooling advice in preparation for my new computer. Of course if this was normal system I wouldn't bother you all like this, but this one is a little different. I'm about halfway done with the case, it's a complete from-scratch build with stainless steel tubing, but the special thing about it is that the frame is part of the water cooling system (the second one I've done this way, here's the first:

http://i5.photobucket.com/albums/y156/zackbass/IMG_0023compressedSmall.jpg ) and it's being built like a safe. That means innocent things like unguarded airholes are a no-no. I've got a detailed worklog over at bit-tech:http://forums.bit-tech.net/showthread.php?t=89645 that I'd suggest skimming to get a feel for the design but I'll lay out a summary here.

Here's a render that shows off the basic structure:

Its footprint is about 19.5"x14.5". The large bottom section and the two uprights are connected internally and form the reservoir while the connecting section up top is internally separated and is the distribution manifold. The two side doors lift up on hinges at the top. A transmission cooler will be mounted on small standoffs to the slanted section of the outside of each door.

The system is going to be entirely fanless, and to add to that it's being built like a safe so internal airflow is going to be almost nonexistant. I won't be overclocking, but the load on the system is going to be pretty substantial.

Here's a partial list of major heat contributing hardware inside the case:

Dual Core Pentium 4

Undetermined mobo

Antec Neopower

Two 7200RPM HDDs

High end video card

Eheim 1048 (I hope it's beefy enough)

Now, I wouldn't try something like this if I didn't know what I was doing, so there's no need telling me that it's too hard or that it'll never work, so let's get down to business and make it work.

My two transmission coolers just came in today. They are Fluidyne units, but they're unlike anything I've ever seen before. Here are some pics:

In the center of the bottom picture you can see the internal structure of the tubes. It's a very interesting design, my gut feeling is that they're extemely effective but pretty restrictive (confirmed by the "put my mouth over the inlet and blow" test). I have yet to decide whether to run them in series or parallel. Some air holes will be drilled through the doors directly underneath the rads to get some air circulation (the rads guard againt a breach through the holes). I've yet to find a place where I can put the inlet holes and not compromise security. I may just have to pick a spot out in the open and use some steel mesh to cover it.

The power supply modification is almost complete. I decided to go with a copper riser connected to a U-tube. It's all welded with near 100% penetration, so it's basically solid copper (no nasty solder interfaces to worry about). This is it in its most finished state:

So to recap we have the following to work with:

A custom case with a very large reservoir that slowly bleeds off heat

An Eheim 1048

A water cooled PSU

Two restrictive but highly effective rads

Nearly zero airflow

Keeping it in the spirit of a secure safe

What I need is suggestions on how to pull this off effectively and details on potential trouble spots. What components need to be water cooled since they don't have any airflow? Should I be worried about the northbridge or mobo power circuitry? How about the hard disks? I can whip up waterblocks for anything no problem, I have a Bridgeport milling machine in my shop and know how to use it.

I also need to pick waterblocks for the CPU and GPU. I'm not afraid to lay out some cash for the good stuff, I've come this far already. I would love to have someone's custom work but I'm not sure of what's out there and how to buy it.

Congratulations on making it to the end of my question(s), any and all help besides the assumed "you're crazy and it'll never work" is very much appreciated.