- Joined

- Mar 26, 2012

- Location

- Edmond, OK

- Thread Starter

- #141

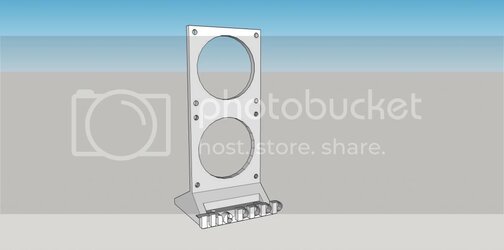

Was a gorgeous day today here in Oklahoma. Decided to spend a little time in the garage working up a prototype for a pump stand. Because I am in love with the look of the large EK pump tops, my current plan is to put them right in front of a window so they can be seen easily. I think I want the reservoir in the front window....so the only logical place left that doesn't block the view of anything critical is right behind the reservoir on the left side of the case. And I need to stack them vertically. Not just because I don't have enough floor space over there ( I don't ), but because I want them to both be stacked against the window. So....

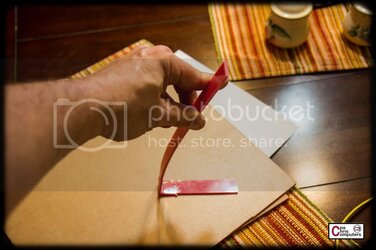

First I went to Lowe's and grabbed about $6 bucks worth of aluminum strips. I'm doing the prototype in aluminum because it is so darn easy to work with and so cheap. Once I have a design that I think works, I may investigate doing it in other materials. My first attempt here is using 1/16 inch thick strips. These are pretty soft, so I'll have to see if they can support the weight of the pumps.

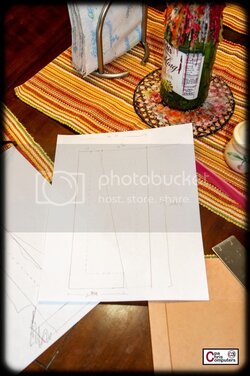

Sketched out rough dimensions. Nothing to precise here. This is just a prototype.

Got my hacksaw out and went to cutting.....

This stuff is fairly thin....so it didn't take long. Maybe 10 minutes. Now I have these 6 strips....

Did some real quick touchups on the ends with a file. Just a few minutes. Not trying to make them look good....just trying to keep from cutting myself.

Drilled some quick holes.....

When I did a test fit to see if the holes lined up on the pump....I found out that the pump cover was just large enough where it kept the strip from coming in far enough to line up with the holes. Fail. So....I just filed out a little "v" shape right where the cover was touching the strip.

Didn't take much....now it fits.

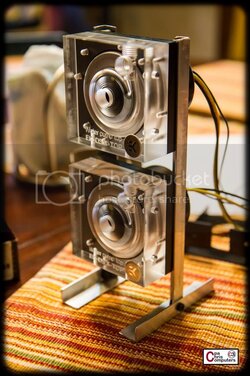

Got my pieces all cut, filed and drilled. Let's put it together.

[

First I put the long vertical strips on the back of the pumps. I used the EK vibration dampeners that come with the D5 mounting kits. I attached the dampeners to the pumps, and then attached the aluminum strips to the dampeners. Was able to use screws and washers from the EK D5 mounting kit also.,

Then I attached the vertical strips to the base strips with 8mm M4 bolts and nuts.

It actually feels very solid even without the support strips I cut....but I went ahead and put one on the back anyway.

The idea would be to mount this directly to the midplate in right about this location. I'd have to do something to decouple it from the floor....but you get the idea. There is just enough room in front of it to reservoir. I might even be able to extend a little mounting arm off the side of this and attach the reservoir to it.

If I stick with aluminum, these would be powder coated with the same black powder that CaseLabs uses on the interior....so they would blend right in.

The pumps are about 1 inch higher than I think I want them. So....when I redo this, I'll bring them down a little so they are more centered in the window.

Would love some feedback on improvements for the pump stand...or other ideas for how to mount these big bright beautiful babies. Oh wait....this is the PPPP....not the BBBB. Ok...how about....ideas on how to mount these particularly pretty plexi pumps. Word.

First I went to Lowe's and grabbed about $6 bucks worth of aluminum strips. I'm doing the prototype in aluminum because it is so darn easy to work with and so cheap. Once I have a design that I think works, I may investigate doing it in other materials. My first attempt here is using 1/16 inch thick strips. These are pretty soft, so I'll have to see if they can support the weight of the pumps.

Sketched out rough dimensions. Nothing to precise here. This is just a prototype.

Got my hacksaw out and went to cutting.....

This stuff is fairly thin....so it didn't take long. Maybe 10 minutes. Now I have these 6 strips....

Did some real quick touchups on the ends with a file. Just a few minutes. Not trying to make them look good....just trying to keep from cutting myself.

Drilled some quick holes.....

When I did a test fit to see if the holes lined up on the pump....I found out that the pump cover was just large enough where it kept the strip from coming in far enough to line up with the holes. Fail. So....I just filed out a little "v" shape right where the cover was touching the strip.

Didn't take much....now it fits.

Got my pieces all cut, filed and drilled. Let's put it together.

[

First I put the long vertical strips on the back of the pumps. I used the EK vibration dampeners that come with the D5 mounting kits. I attached the dampeners to the pumps, and then attached the aluminum strips to the dampeners. Was able to use screws and washers from the EK D5 mounting kit also.,

Then I attached the vertical strips to the base strips with 8mm M4 bolts and nuts.

It actually feels very solid even without the support strips I cut....but I went ahead and put one on the back anyway.

The idea would be to mount this directly to the midplate in right about this location. I'd have to do something to decouple it from the floor....but you get the idea. There is just enough room in front of it to reservoir. I might even be able to extend a little mounting arm off the side of this and attach the reservoir to it.

If I stick with aluminum, these would be powder coated with the same black powder that CaseLabs uses on the interior....so they would blend right in.

The pumps are about 1 inch higher than I think I want them. So....when I redo this, I'll bring them down a little so they are more centered in the window.

Would love some feedback on improvements for the pump stand...or other ideas for how to mount these big bright beautiful babies. Oh wait....this is the PPPP....not the BBBB. Ok...how about....ideas on how to mount these particularly pretty plexi pumps. Word.

look closely before you post dummy

look closely before you post dummy