- Joined

- Apr 4, 2011

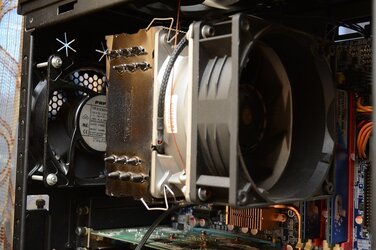

Interesting, So I added a pull-up resistor of 15K. Fixed it. I now have control of the TFC1212DE by motherboard PWM. Next step is to make a small version of the inverter and find a place to put them. Also decide if i dare get a second and use them as my CPU's fans.

glad you made it

ummmmm,

I really don't know what's the difference between the G06 vs G01

my best bet, they were a revision number. maybe

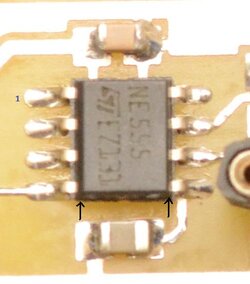

but, I got 4 of this SanAce.

3 of them were ended up with G03, while the other one was G06 as can be seen on the picture.

two of the G03 were made in the Philippine, and one of them was made in Japan.

the interesting part is, with the very same controller; one of the G03 which made in the Philippine can be run @1200rpm without breaking my noise tolerances.

while the other G03 which also was made in the Philippine only can be run <700rpm. beyond that, this fan's quite annoying to me.

as for the last G03 which made in Japan, I can only run it @900rpm before it breaks my limit.

as for the G06, it mostly spend its time within the closet as I haven't really try it for anything