-

Welcome to Overclockers Forums! Join us to reply in threads, receive reduced ads, and to customize your site experience!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Please help! Coolant not going any further

- Thread starter TheAkira

- Start date

- Thread Starter

- #3

- Joined

- Sep 13, 2015

Like Blaylock said it looks like you have a blockage in your block or rad possibly that is causing the restriction in the system which is creating extra head pressure against the pump. By adding more fluid to the reservoir it is allowing the extra pressure from the fluid in the reservoir to help overcome the head pressure from the restriction. I guess there is the possibility that the system is airlocked but I doubt this is the cause. You could try tipping the system on its side while filling/priming to see if you can get the air to move if it is airlocked. MY money is on a restriction somewhere thoguh especially if the system was not flushed prior to assembaly.

- Thread Starter

- #5

Like Blaylock said it looks like you have a blockage in your block or rad possibly that is causing the restriction in the system which is creating extra head pressure against the pump. By adding more fluid to the reservoir it is allowing the extra pressure from the fluid in the reservoir to help overcome the head pressure from the restriction. I guess there is the possibility that the system is airlocked but I doubt this is the cause. You could try tipping the system on its side while filling/priming to see if you can get the air to move if it is airlocked. MY money is on a restriction somewhere thoguh especially if the system was not flushed prior to assembaly.

The system wasn't really flushed. So, what should I do now? disassembly? (Please dont)

- Joined

- Sep 13, 2015

Preferably the whole system should be torn down and flushed and the fluid in the loop discarded. You may get away with just pulling the block and radiator and flushing them but you risk having crap left in the fluid or pump that could cause blockage again or damage the pump. You could start with just pulling the block and trying to flush that and catch the flush water to see if anything comes out. This could be a good indication of if you actually had a blockage or if there was a problem with your pump.

Well, to be brutally honest any new component should be properly flushed prior to filling. If you read the instructions to any of your components they will tell you that there may be manufacturing particles inside of radiators and other pieces. So you need to make the determination if it's worth doing a full teardown now before you're up and running or if you're willing to risk a blockage while you're away and possibly damaging your gorgeous rig (which it most definitely is!).

If it's just an airlock like Lockekey suggests then simply rocking the case back and forth and front to back could force the air to pass. But my guess it's probably a blockage, partial or fully would be enough to restrict you flow rate like that.

If it's just an airlock like Lockekey suggests then simply rocking the case back and forth and front to back could force the air to pass. But my guess it's probably a blockage, partial or fully would be enough to restrict you flow rate like that.

- Thread Starter

- #8

That was really my bad, guys. Thanks for the help. I'll not risk it. I'll remove the fluid and clean everything up. Distilled water, right? The only thing that I don't understand is how can these small particles make such pressure against the pump.

- Joined

- Jan 10, 2012

it may not be the block, it could be the rad.

all kinds of things can be in the system, pull it all out and all apart, pour each piece full of distilled water, shake hard and long, pour water through each piece, blow through each piece.

all kinds of things can be in the system, pull it all out and all apart, pour each piece full of distilled water, shake hard and long, pour water through each piece, blow through each piece.

- Joined

- Sep 13, 2015

I use hot tap water and a little vinegar for my primary rinse followed by a secondary rinse of tap water and a final rinse of distilled water.

As to how the little particles stop things. First, some of the particles that can come out of the radiator are actually quite large. Secondly if you have ever seen a cpu pick disassembled the water channels are very tight. All it takes is for one larger particle to get sick and then it acts as a father point for smaller particles to stick and grow. By even partially blocking the block channels you can produce enough head pressure to overcome the pump.

As to how the little particles stop things. First, some of the particles that can come out of the radiator are actually quite large. Secondly if you have ever seen a cpu pick disassembled the water channels are very tight. All it takes is for one larger particle to get sick and then it acts as a father point for smaller particles to stick and grow. By even partially blocking the block channels you can produce enough head pressure to overcome the pump.

- Thread Starter

- #11

Thanks for the good tips guys. It'll definitely helps me and probably other people as well. Im already working on the cleaning, I'll post the results here tomorrow. I was thinking about it... The fluid didn't even pass through the rad and block. Does it change anything?

Best of luck Akira.

It doesn't change anything. It all needs to be flushed. Google rad dance and you'll see what we're talking about. Don't forget to disassemble the CPU block and rinse to make sure there are no particles. Rinse out the pump and reservoir too. I would not disassemble the pump as this will usually void your warranty but everything else, yes.

It doesn't change anything. It all needs to be flushed. Google rad dance and you'll see what we're talking about. Don't forget to disassemble the CPU block and rinse to make sure there are no particles. Rinse out the pump and reservoir too. I would not disassemble the pump as this will usually void your warranty but everything else, yes.

- Joined

- May 7, 2005

what kind of fittings are you using on your cpu block also what kind of cpu block is it? make sure the fittings attached to your cpu block arent bottomed out. some fittings have longer threaded parts. or if you use adapters etc they may also have threaded parts that bottom out.

- Joined

- Jul 26, 2004

what kind of fittings are you using on your cpu block also what kind of cpu block is it? make sure the fittings attached to your cpu block arent bottomed out. some fittings have longer threaded parts. or if you use adapters etc they may also have threaded parts that bottom out.

+1

- Joined

- May 22, 2011

- Location

- USA

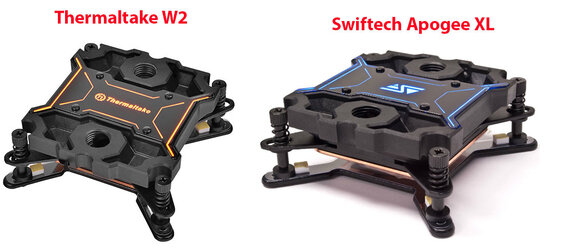

I believe the OP is using the TT W2 CPU block. Identical to the Swiftech XL block I use.

+1 all around. Great tips. I would also recommend on tearing it down and starting all over. The good news is, you already got your hard tubing done.

Carefully clean it up and investigate while making sure once you're putting it all together, your O-rings, gaskets, etc, are put in proper place to create that original seal with no debris in the way.

Keep us up to speed.

One thing you could test is blowing through the block and radiator to see if it is hard to blow through one or the other. Did you check the in/out ports on the cpu block to make sure coolant flow was in the correct direction?

what kind of fittings are you using on your cpu block also what kind of cpu block is it? make sure the fittings attached to your cpu block arent bottomed out. some fittings have longer threaded parts. or if you use adapters etc they may also have threaded parts that bottom out.

+1 all around. Great tips. I would also recommend on tearing it down and starting all over. The good news is, you already got your hard tubing done.

Carefully clean it up and investigate while making sure once you're putting it all together, your O-rings, gaskets, etc, are put in proper place to create that original seal with no debris in the way.

Keep us up to speed.

- Thread Starter

- #17

Sup guys.

I've found the reason for this problem, it's kind of embarrassing but... **** happens, right?. I'll talk about it in a sec.

First I would like to thanks you all for the support. I did the complete disassembly and flushing and it was really necessary, rad was very dirty.

But even after that the issue remained. So I removed the CPU block and the radiator from the system, leaving only the pump+res and 2 tubes. Still the same. So, in this way the only possible thing was the pump.

My power supply doesn't have the exact cable to connect the pump so I had to use some wires and make a workaround. Turns out, I was connecting the wires incorrectly. The pump was working but not with all the power.

Yea, shame on me. It could have burn my pump

Fortunately, I changed the wires and everything started to work propelly. I did the complete fillment, removed the air of the system, leak test, etc.

Here's the result.

I've found the reason for this problem, it's kind of embarrassing but... **** happens, right?. I'll talk about it in a sec.

First I would like to thanks you all for the support. I did the complete disassembly and flushing and it was really necessary, rad was very dirty.

But even after that the issue remained. So I removed the CPU block and the radiator from the system, leaving only the pump+res and 2 tubes. Still the same. So, in this way the only possible thing was the pump.

My power supply doesn't have the exact cable to connect the pump so I had to use some wires and make a workaround. Turns out, I was connecting the wires incorrectly. The pump was working but not with all the power.

Yea, shame on me. It could have burn my pump

Fortunately, I changed the wires and everything started to work propelly. I did the complete fillment, removed the air of the system, leak test, etc.

Here's the result.

- Joined

- Jul 26, 2004

Very glad you got your system up and running it looks nice !

What kind of power connector does your Pump have that you have yo make one ? isnt it a PWM 4 pin or a reg 3 pin fan connector ? If it is one of these you can probably plug it into your motherboard and make use of temp vs speed control for your pump .

What kind of power connector does your Pump have that you have yo make one ? isnt it a PWM 4 pin or a reg 3 pin fan connector ? If it is one of these you can probably plug it into your motherboard and make use of temp vs speed control for your pump .

- Thread Starter

- #19

Very glad you got your system up and running it looks nice !

What kind of power connector does your Pump have that you have yo make one ? isnt it a PWM 4 pin or a reg 3 pin fan connector ? If it is one of these you can probably plug it into your motherboard and make use of temp vs speed control for your pump .

The pump has 3 pins, my power supply have only 4 pins connector. I used 3 wires to connect this connector in the pump, I went by the wire colors and the pump did turn on (incorrectly). So I thought "well, this is working".

Similar threads

- Replies

- 2

- Views

- 215

- Replies

- 4

- Views

- 144

- Replies

- 5

- Views

- 172