- Joined

- May 7, 2011

- Location

- Cook->Kent

This seems like the best place to pop this.

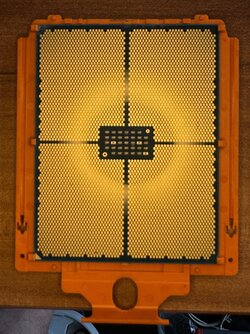

My sig has my forthcoming rig that I'm working on. For no particular reason, I decided to lap this thing. The CPU, given what it is, took a little forethought and I thought I'd had it figured out.

I'd used the socket blank from another board to attach to the back side of the CPU, both for protection and a little extra grabbing surface. A little electrical tape to seal them together (which worked quite well) and away we went.

After a few hours on that as well as the heat sink, I decided that this is a bit of a PITA and found that there's a local lapping supplier and service company practically just up the road. For a relatively low price, I decided to see whether they would do it. Fortunately they will and I'm dropping it off tomorrow.

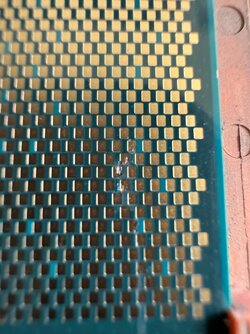

However, in cleaning up the CPU from the initial work I did, I quickly discovered the error of my ways.

But wait...

Ehhh...

Yeah. That had me britting shicks. I learned that, while the CPU blank will cover things nicely, it also partly sits directly on the pads. D'OH!

The motion and the slurry I'd created with some of the finer grit paper got where I'd not intended it to go and...there ya go.

Fortunately, it seems it's superficial as there doesn't seem to be an issue with the CPU based on some basic initial tests. This could have been a stupidly expensive lesson learned. Fortunately, it has become an inexpensive, but very valuable lesson learned.

And for the record, I'd seen info in the past that some previous gen Threadripper IHSs were not copper. This most definitely is.

My sig has my forthcoming rig that I'm working on. For no particular reason, I decided to lap this thing. The CPU, given what it is, took a little forethought and I thought I'd had it figured out.

I'd used the socket blank from another board to attach to the back side of the CPU, both for protection and a little extra grabbing surface. A little electrical tape to seal them together (which worked quite well) and away we went.

After a few hours on that as well as the heat sink, I decided that this is a bit of a PITA and found that there's a local lapping supplier and service company practically just up the road. For a relatively low price, I decided to see whether they would do it. Fortunately they will and I'm dropping it off tomorrow.

However, in cleaning up the CPU from the initial work I did, I quickly discovered the error of my ways.

But wait...

Ehhh...

Yeah. That had me britting shicks. I learned that, while the CPU blank will cover things nicely, it also partly sits directly on the pads. D'OH!

The motion and the slurry I'd created with some of the finer grit paper got where I'd not intended it to go and...there ya go.

Fortunately, it seems it's superficial as there doesn't seem to be an issue with the CPU based on some basic initial tests. This could have been a stupidly expensive lesson learned. Fortunately, it has become an inexpensive, but very valuable lesson learned.

And for the record, I'd seen info in the past that some previous gen Threadripper IHSs were not copper. This most definitely is.