- Joined

- Jan 18, 2009

- Location

- Clearwater FL

I hadn't even tried the washer mod yet, have been messing about some things and have some MX-3 on the way to redo a few things.

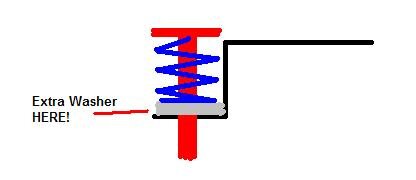

I have used washer sets similar to these before at work for a few applications, I think when I re-apply things and put a washer on there Im going to put a set of washers simliar to this one under the retaining clips.

Tiny bit of molybdenum paste on those babies they should really float nicely.

http://www.ricelake.com/docs/viewProductkits.php?productID=33220

Should really even the pressure out.

I'm still dwelling on trying the CCTF thing out on this TRUE in my head, have to see, I'll take another look at it once it's off again

There are different ones out there I just found that one as an example, but along the lines of what I have in mind at any rate.

*EDIT*

Like I said there are different ones out there and was using it as an example

http://mortonmachine.thomasnet.com/v...ers?&forward=1

I have used washer sets similar to these before at work for a few applications, I think when I re-apply things and put a washer on there Im going to put a set of washers simliar to this one under the retaining clips.

Tiny bit of molybdenum paste on those babies they should really float nicely.

http://www.ricelake.com/docs/viewProductkits.php?productID=33220

Should really even the pressure out.

I'm still dwelling on trying the CCTF thing out on this TRUE in my head, have to see, I'll take another look at it once it's off again

There are different ones out there I just found that one as an example, but along the lines of what I have in mind at any rate.

*EDIT*

Like I said there are different ones out there and was using it as an example

http://mortonmachine.thomasnet.com/v...ers?&forward=1

Last edited: