- Joined

- Mar 22, 2012

- Location

- Camp Pendleton Ca

- Thread Starter

- #41

MarineTuck, those 1.2 signs can be found at the link I provided, but since I only linked it in the text you may have missed it. Here it is in full: http://www.compliancesigns.com/DOT-13241.shtml?ref=champ They sell stickers in 1", 2.5", 7", and more. Heck, you can even get aluminum signs, plastic signs and other options.

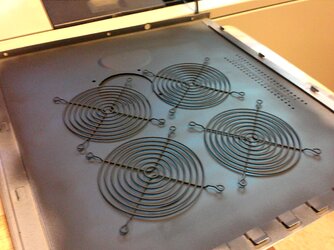

Here's a thought for the fans that are visible...you know how sometimes you can make a pattern look like a picture when it's spun at the right speed? Maybe you could research that and paint that pattern on the blades, then attach a manual fan controller on it so you can get just the right speed out of it to get your "picture".

Another idea to go along with the 20MM idea. If you want to elevate it off the floor instead of using rubber feet, why not find some surplus 20MM casings in brass (those are MUCH harder to find because we've been using aluminum cases for a long time), and either cut them to desired length and attach to the bottom of the case or epoxy them at the corners to be able to see the whole cartridge. If you have contacts, you could even get a few old target practice projectiles and put those in to make it complete. Just remember to polish the brass and then seal it with a spray on urethane. If you can only get the aluminum case, oh well, they still look cool. Then again, since you're on a Marine base you may (I don't know what they have out there) be able to procure expended 25MM from the LAV. Other than the markings, there's not a lot of difference size-wise. I could tell by looking at it and some others could too, but the average joe would have no clue.

O and on the stickers i looked at that sight... didnt look at the other tabs lol