- Joined

- Feb 21, 2006

- Location

- Oklahoma City

I am in the process of building my first computer and I want to do water cooling. After giving it a lot of thought and doing a lot of research, it looks like using a small 5000 BTU A/C unit to cool the liquid will be the best route. Since this is my first computer, I do not want to do a true phase change system. However, I would like to know any and all details of modding the A/C unit.

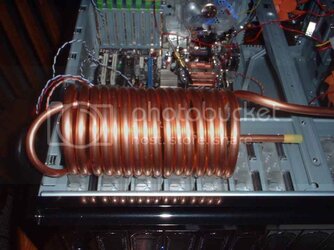

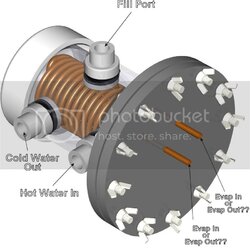

What I plan on doing is replacing the evaporator with a copper coil in a PVC pipe. The coolant will run through the pipe. The fabrication is simple and I've done much more complicated fabrication on aquarium systems. What I need help with is the evacuating/charging/etc of the system. I've read many threads and done many searches (here and internet), but all I've found are bits and pieces of data and nothing solid and cohesive.

As I understand it, after the fabrication is done and everything has been brazed, I need to vacuum out the system, charge it with nitrogen to 200 - 300 PSI, discharge the nitrogen, vacuum out the system and hold a vacuum for a couple of hours and repeat a few times to remove any air and moisture. Is this correct? If so, after this is done, to what pressure do I charge the unit with Freon(I know, general term...)?

Also, what it that tool called with three tubes and two gauges? How, exactly, does this tool help me? What are the three lines for? I think I've read that one is for vacuuming, one is for charging and the other is for...?

I hate to post such a newbie question, but I'm a newbie. We all have to start somewhere, right?

What I plan on doing is replacing the evaporator with a copper coil in a PVC pipe. The coolant will run through the pipe. The fabrication is simple and I've done much more complicated fabrication on aquarium systems. What I need help with is the evacuating/charging/etc of the system. I've read many threads and done many searches (here and internet), but all I've found are bits and pieces of data and nothing solid and cohesive.

As I understand it, after the fabrication is done and everything has been brazed, I need to vacuum out the system, charge it with nitrogen to 200 - 300 PSI, discharge the nitrogen, vacuum out the system and hold a vacuum for a couple of hours and repeat a few times to remove any air and moisture. Is this correct? If so, after this is done, to what pressure do I charge the unit with Freon(I know, general term...)?

Also, what it that tool called with three tubes and two gauges? How, exactly, does this tool help me? What are the three lines for? I think I've read that one is for vacuuming, one is for charging and the other is for...?

I hate to post such a newbie question, but I'm a newbie. We all have to start somewhere, right?